As cool and wonderful as Lego is, those plastic bricks can be tricky to handle if you want to step up from mere constructive play into serious custom-built prototyping. UberBlox hopes to fill that gap. It's a metal construction set and prototyping system with a single-connector locking mechanism and a variety of control boxes for accommodating whatever computer connection or automation needs a project might have.

"It is difficult to make automated machines without years of developing skills and know-how," UberBlox Systems founder Alex Pirseyedi tells Gizmag. "You need to know about technical design principles, not to mention the skills required to fabricate and assemble parts accurately to make such complicated machines work."

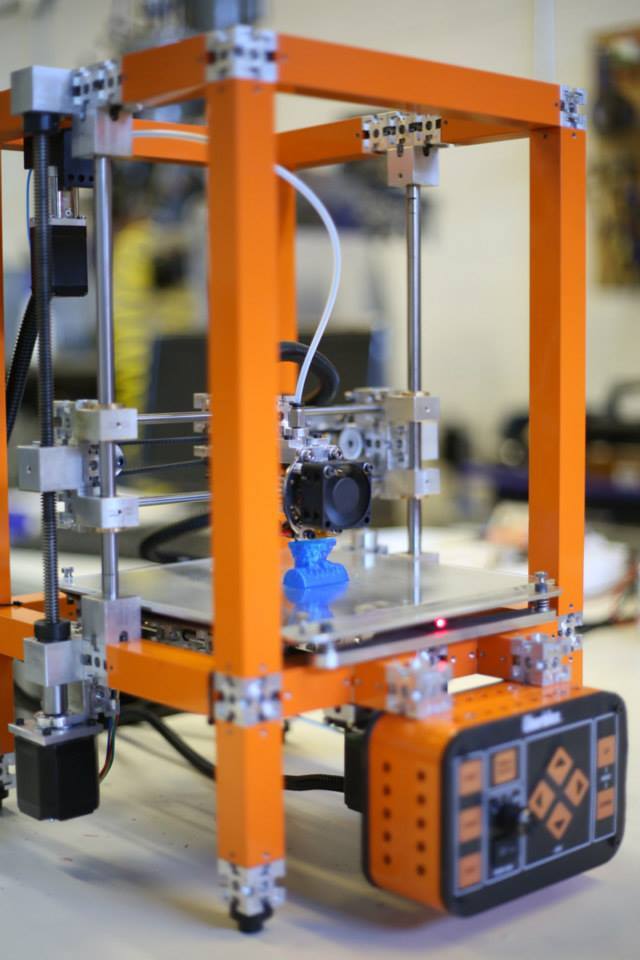

UberBlox was born of the need for a solid, easy-to-use modular system that enables makers to build and test their robots, 3D printers, smart systems, and other computer-programmed automated machines. Pirseyedi notes that, while the traditional plastic building block sets "are great for quickly and easily making something," they can't handle the kind of rigidity and accuracy these automated machines require. UberBlox, he argues, bridges the gap by combining the lower barrier of entry of something like Lego with the higher technical needs of a typical maker.

"Even with today’s readily available aluminum T-slot mechanisms, you still need to cut, drill, mill, fit, re-try, re-cut, [and] deal with a huge number of choices for connecting parts," explains Pirseyedi. "And [you have to] do all this accurately with tools and equipment that you may not necessarily have easy access to or know how to operate properly. UberBlox eliminates all that. You simply imagine a machine idea within the context of the system, and you start assembling parts, mostly with a single small tool. The supporting electro-mechanic, electronic, and software components then help you bring it to life."

As for specific examples of what UberBlox might be helpful to produce or prototype, Pirseyedi has suggestions. The big one his team is pushing is 3D printing, with much of the marketing material revealed so far showing how the kit can become a functioning 3D printer. If you really just want a 3D printer, of course, you can buy one preassembled or packaged in a more tailored kit. But UberBlox is for the curious. It's targeted at people who "have a desire to make their own so that they can learn engineering and technical skills as well as be able to tweak their system however they like," says Pirseyedi.

Moreover, he adds, UberBlox allows for quick and easy testing of new design ideas for either entire 3D printing systems or portions of them, which is a popular pursuit of many in the maker community, without getting bogged down in the fabrication process. "After all, that is one of the reasons we’ve had such an explosion in interest in low-cost 3D printers in the past couple of years," he says.

Besides 3D printers, the system could also "easily" be used to build loads of different types of robots, including manipulator arms, rovers, and humanoids, as well as laser cutting and engraving or CNC milling and routing machines.

It isn't clear yet exactly what parts will be included in UberBlox kits, but they will include both basic blocks and reconfigurable parts, such as motors, moving components, electronics, and "Brain-Box" controllers for do-it-yourself boards, such as Arduino and Raspberry Pi. It sounds like there'll be multiple configuration options, but the UberBlox team is keeping the details quiet on this and pricing until it launches a Kickstarter campaign later this month.

The upcoming UberBlox Kickstarter will also reveal how the connection mechanism works, and if it surpasses its goal the team may be able to develop a 3D software tool designed specifically for drag-and-drop assembly of virtual UberBlox parts to aid in the design process. Regardless of any stretch goals, the team will release 3D models of UberBlox parts to backers "at some point in time" so that they can play around with them in their CAD or 3D modelling software of choice.

You can see a video of UberBlox and an UberBlox-assembled 3D printer in action below.

Source: UberBlox

Update (March 30, 2014): The UberBlox Kickstarter campaign is now live.