Carbon fiber may boast an impressive strength-to-weight ratio, and it looks cool, but it does have at least one shortcoming when compared to other building materials – it's difficult to recycle. Nonetheless, Trek Bicycle has begun a program that will see much of the company's waste carbon fiber being sent to a specialized recycling facility, where it will be processed for use in other products. According to the Cyclingnews website, the initiative should keep up to 54,000 pounds (24,500 kg) of the material out of landfills and in use, every year.

Trek initially entered into a three-month pilot project with South Carolina's Materials Innovation Technologies and its subsidiary, MIT-RCF. Last Thursday (April 21st, 2011), the bicycle-maker announced that the program will continue indefinitely.

The carbon fiber selected for recycling will include trimmings left over from frame production, non-compliant molded parts, and selected frames that have been returned on warranty claims, or damaged in testing.

While the exact figures will vary, the company has reportedly already been sending off between 3,500 and 4,500 pounds (1,590 to 2,040 kg) of carbon fiber every month.

MIT-RCF's recycling process starts with the waste material being cut into one-inch squares. Those squares are then subjected to pyrolysis, a process in which the carbon fiber is heated in an almost oxygen-free environment, burning away its resin content and freeing up the fibers. Those fibers can then be combined with new resin, to form "chopped fiber composites." While they don't offer the same strength or stiffness as virgin carbon fiber, MIT-RCF will be using the chopped fibers in reinforced thermoplastic applications where such qualities aren't crucial.

Not only does the process divert waste carbon fiber from the trash heap, but it's also said to be very energy-efficient. "It actually takes 96 percent less energy to reclaim a carbon fiber than it does to build a new virgin fiber," Materials Innovation Technologies president Jim Stike told us.

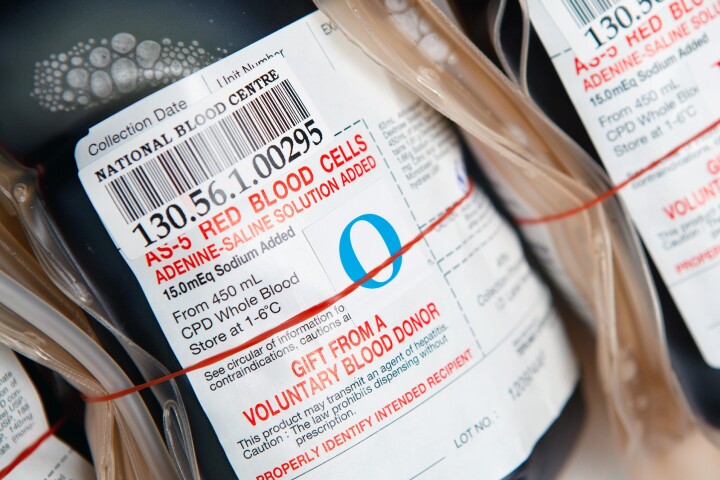

The company is looking into automotive, aerospace, medical, and recreational applications for the technology.

Source: Cyclingnews