Silicon

-

Two of the first-ever desktop computers have been found in storage boxes at Kingston University in London. A milestone in human achievement, the Q1 microprocessor computer was released more than half a century ago, and only one other is known to exist.

-

Researchers developed a nanospiked surface that was 96% effective in destroying a common virus responsible for causing respiratory illnesses in children. The technology could safeguard researchers, health workers and patients from viral spread.

-

Scientists have found that a “superatomic” material is the fastest and most efficient semiconductor ever. Taking advantage of a tortoise-and-hare mechanism, the new material can transport energy much faster than silicon.

-

Back in April, xMEMS Labs revealed solid-state technology aimed at replacing coil-based speakers in audio wearables like in-ear monitors. Now the company has partnered with Creative Technology for an upcoming pair of true-wireless earphones.

-

A brand new form of silicon might help extend its use into the future. Engineers at North Carolina State University have discovered a material called Q-silicon, with new properties that could have important uses in quantum computers and spintronics.

-

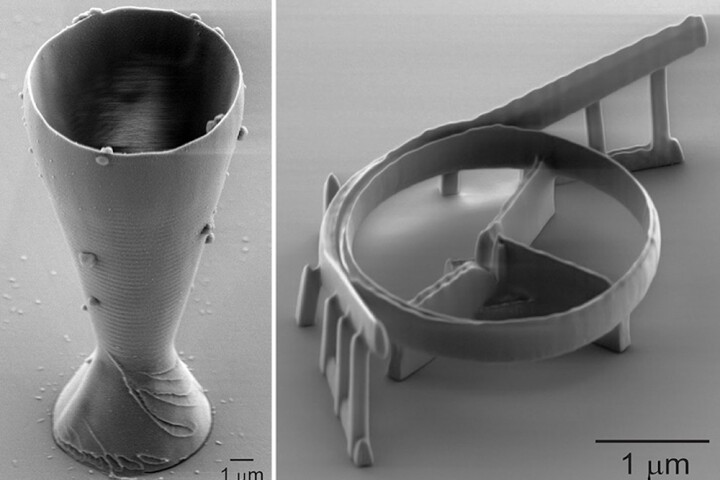

Scientists have created the world’s smallest wine glass, narrower than a human hair. Made out of actual glass, the model is a test run of a new 3D-printing process that could help make nanoscale glass components for electronic and optical devices.

-

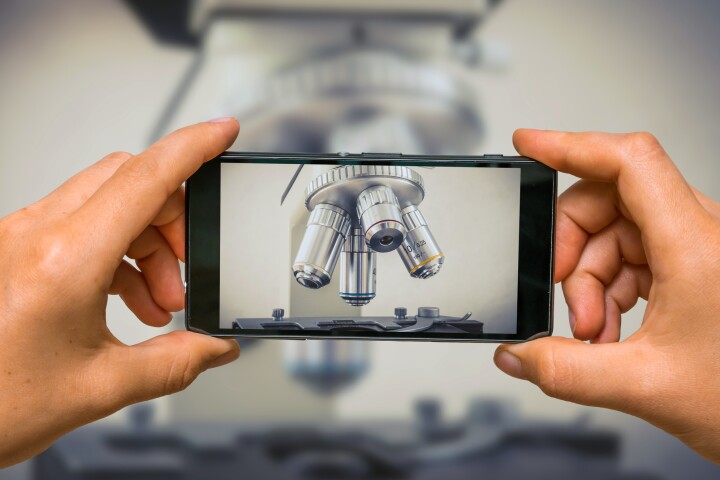

Move over, macro: researchers have created the world’s smallest silicon LED and holographic microscope, and among its uses is a hack that'll let you use your smartphone to view objects as tiny as a single human skin cell in brilliant high resolution.

-

xMEMS Labs is aiming to replace century-old coil-based speaker technology with silicon-based microspeakers, and has launched three Solid-State Fidelity solutions for use in upcoming true-wireless earphones, in-ear monitors and digital hearing aids.

-

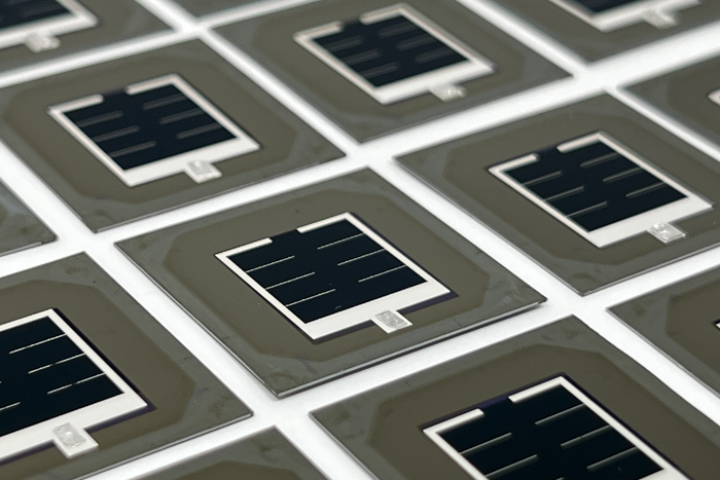

The dynamic duo of silicon and perovskite continue their rampage through the solar cell industry. Researchers at KAUST have developed a new silicon/perovskite tandem solar cell with a record-breaking efficiency.

-

Sila announced this month that its Titan Silicon nano-composite silicon anode is now available. The anode will feature in the electric Mercedes-Benz G-Class and promises range increases up to 20% and dramatic charging time decreases.

-

Lightning's wild LS-218 superbike and Strike sportsbike are among the first EVs to get Enevate's super-high density, ultra-fast charging, next-gen silicon-anode batteries – which charge almost as fast as your buddies can fuel up their dinosaur burners.

-

Perovskite and silicon are proving to be a formidable duo in the world of solar cells, and now they’ve hit a new record efficiency. A team at Helmholtz Zentrum Berlin (HZB) have developed solar cells with an efficiency of over 32%.

Load More