Manufacturing

-

The popular pain-killing drug paracetamol, also known as acetaminophen, has always been made from chemicals derived from environmentally damaging coal tar or crude oil. Now researchers have devised a greener way of producing the drug using wood.

-

Humanoid robots are entering the workforce. Following in the footsteps of Figure 01 at BMW and Digit in Amazon's R&D facility, Apptronik's Apollo bot is helping skilled human workers build cars for Mercedes-Benz.

-

Amid ongoing global shortages of semaglutide, the active ingredient in medical sensations Ozempic and Wegovy, researchers have uncovered a way to make 10 times more of the stuff, producing a therapeutically similar version of the in-demand drug.

-

Figure has signed its first commercial deal, and is sending its general-purpose humanoid robots off to start real-world work at BMW's manufacturing plant in South Carolina. Founder and CEO Brett Adcock talks us through this rubber-meets-road moment.

-

Bill Gates-backed startup Antora Energy is preparing to roll out a containerized, modular heat battery, designed to store renewable energy at the lowest possible cost – then release it efficiently as electricity or industrial process heat.

-

Nano-engineering happens all day long in our bodies, and California startup Aether is designing and testing millions of new enzymes to do a range of other useful tasks – like directly extracting battery-grade lithium from sources nobody else can use.

-

Paracetamol and ibuprofen are among the world’s most common painkillers, but manufacturing them requires crude oil. Now, researchers have developed a more sustainable method, creating the drugs out of waste products from the paper industry.

-

Despite its many advantages, glass has one major Achilles' heel – it’s brittle. Now, engineers at Penn State have developed LionGlass, a new form that's not only 10 times more damage resistant, but requires significantly less energy to manufacture.

-

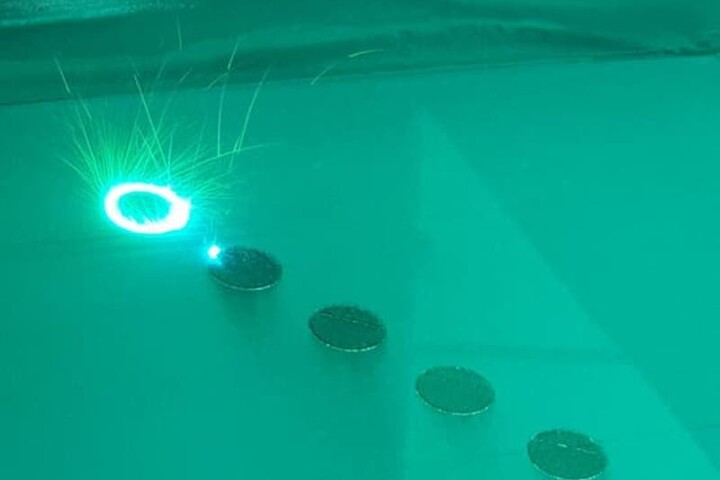

Researchers in New Zealand and Australia have grown tiny metal snowflakes, cubes, rods and other shapes. The nanocrystals form like snow out of a liquid metal, demonstrated an intriguing new potential method for manufacturing nanoscale structures.

-

Engineers have developed a new 3D-printed titanium alloy with a unique microstructure that makes it ultra-strong. Not only is it stronger than other forms of titanium, but it has the highest strength-to-weight ratio of any 3D-printed metal ever made.

-

Industrial heat consumes a huge proportion of global energy. Rondo Energy says its brick-toasting heat storage device is so cheap and efficient that it makes decarbonization an instant no-brainer across a huge range of industries. Bill Gates agrees.

-

Although 3D printing technology continues to improve, it's still limited by relatively long print times and low resolution. A new technology could help, by simultaneously utilizing multiple small print nozzles instead of a single big one.

Load More