Cartilage

-

A clinical trial will soon commence investigating whether nose cartilage can be used to regenerate knee joints that have been severely worn down by osteoarthritis. If successful, the procedure could be an alternative treatment for the condition.

-

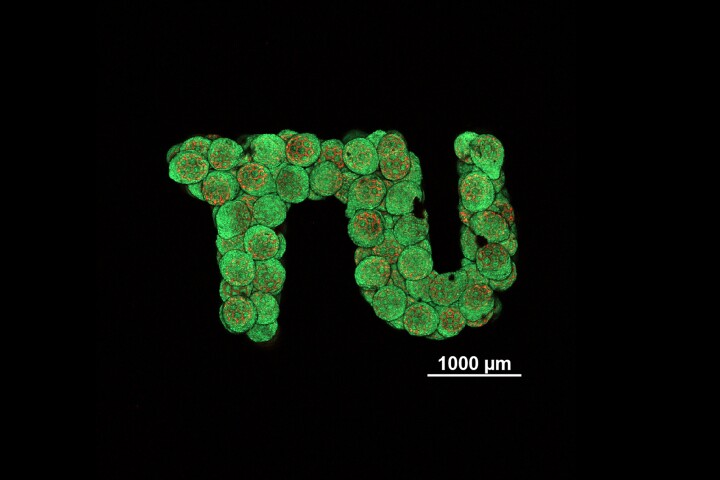

Researchers at TU Wien have developed a new way to grow cartilage from stem cells and guide it into basically any shape required. The breakthrough could lead to better ways to patch up injuries.

-

Researchers have found that osteoarthritis is caused by the depletion of specialized gene-expressing cartilage-forming stem cells and found a way to treat and reverse the condition, instead of just managing its symptoms.

-

In a world first, Budapest Zoo gorilla Liesel has received stem-cell therapy for her arthritis. It's hoped that this groundbreaking procedure, which aims to rejuvenate her damaged joint cartilage, will not just help her but be adapted for human use too.

-

The utility of the humble mussel in the world of medicine has expanded once again. This time, researchers figured out how to use a mussel-based glue to hold stem cells in place long enough to repair cartilage inside a rabbit's body.

-

A torn meniscus, the cartilage in the knee, is a common sports injury, and unfortunately it doesn’t heal well. But researchers in Japan have now identified a hormone that helps repair the cartilage after a surgical treatment.

-

Joint pain is a common ailment of aging, thanks to cartilage’s tendency to wear out. Researchers at Duke University have developed a new hydrogel that’s stronger and more durable than the real thing, which could make for longer lasting knee implants.

-

When cartilage in joints such as the knees gets damaged, it is very slow to heal – if it ever does at all. An experimental new biohybrid material could one day replace it, however, and may even promote the growth of new natural cartilage.

-

Tennis players are susceptible to wrist cartilage injuries, which may not even present any symptoms at first. A van-based MRI system was designed with that in mind, as it can spot such injuries right at the tennis court, before they become serious.

-

By stimulating cells to reproduce, electricity has already been shown to help heal soft tissue injuries. Now, an electricity-producing implantable material likewise appears to boost the regrowth of cartilage in compromised joints.

-

Paleontologists have isolated cartilage cells from an exceptionally well-preserved dinosaur fossil. They still contain traces of biomolecules, and the scientists were even able to tell which stage of the natural cycle specific cells were in at death.

-

A new, dissolving, textile-based stem cell implant has reduced pain and restored hip joint function to dogs with moderate osteoarthritis, in what researchers say could be a first step toward less invasive joint resurfacing in dogs as well as humans.

Load More