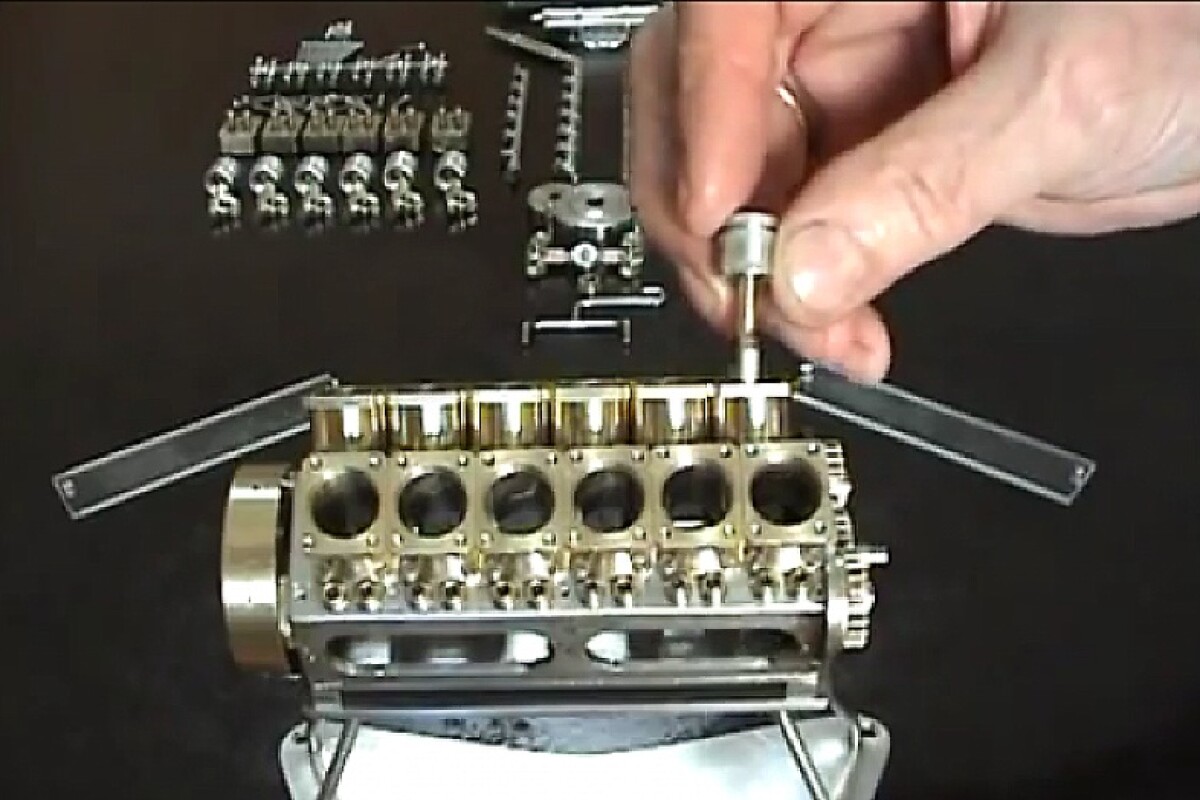

Anyone who appreciates the precision art of engine design ought to get a kick out of this offering from a Spanish engineer named Patelo. Starting with hunks of aluminum, bronze and stainless steel, he spent over 1200 hours designing, milling, turning and drilling what he claims is "probably" the world's smallest V12 engine. Powered by compressed air injection (0.1kg/sq cm), this little marvel boasts a total displacement of 12 cubic centimeters from its twelve 11.3 mm diameter pistons and works like a charm. Best of all, you can see it come together in the detailed video that follows.

Built primarily for educational purposes, Patelo has no plans for selling the mini-motors. In fact, seemingly to prove this lengthy exercise in metallic accuracy was truly a labor of love, he dedicated the engine to his four grandchildren. He crafted all 261 pieces of the engine from scratch, but drew the line with the 222 screws, which he purchased, presumably so he'd have at least a little time to spend with the grandkids.

Here's an English translation of the terms in the video in case you don't have a Spanish dictionary handy (watching it'll be nine minutes and change well-spent):

- Construimos el ciguenal: Building the crankshaft

- Comenzamos el montaje: Begin the installation

- Montamos el ciguenal en el bloque: Fit the crankshaft in the block

- Cojinete de apoyo del ciguenal: Crankshaft bearing support

- Taques: Tappets

- Arbol de levas: Camshaft

- Cojinete de apoyo del arbol de levas: Camshaft support bearing

- Engranajes de la distribucion: Timing gear

- Volante: Flywheel

- Cilindros: Cylinders

- Pistones: Pistons

- Comprobamos con un taladro que todo esta en orden: Check with a drill that everything is in order

- Culatas: Cylinder heads

- Balancines: Rockers

- Varillas de balancines: Rocker shafts

- Colectores de admision: Intake manifolds

- Colectores de escape: Exhaust manifolds

- Tapa de distribucion: Distribution cover

- Bombas de refrigeracion: Cooling pumps

- Enfriador de agua dulce: Fresh water cooler

- Filtro de admision: Inlet filter

- Pruebas de funcionamiento: Function tests

- Camara lenta: Slow motion

- Numero de piezas/tornillos: Number of pieces/screws

- Horas de trabajo: Hours of work

Maybe it's the music in the video but precision machining doesn't get much more exciting than this.