Homes may one day benefit from improved acoustic insulation with an orange flavor after researchers in Spain managed to turn waste material from orange trees into high-performance acoustic insulation. The new material is more environmentally friendly to produce and an improvement in terms of acoustic insulation compared to conventional laminated gypsum boards.

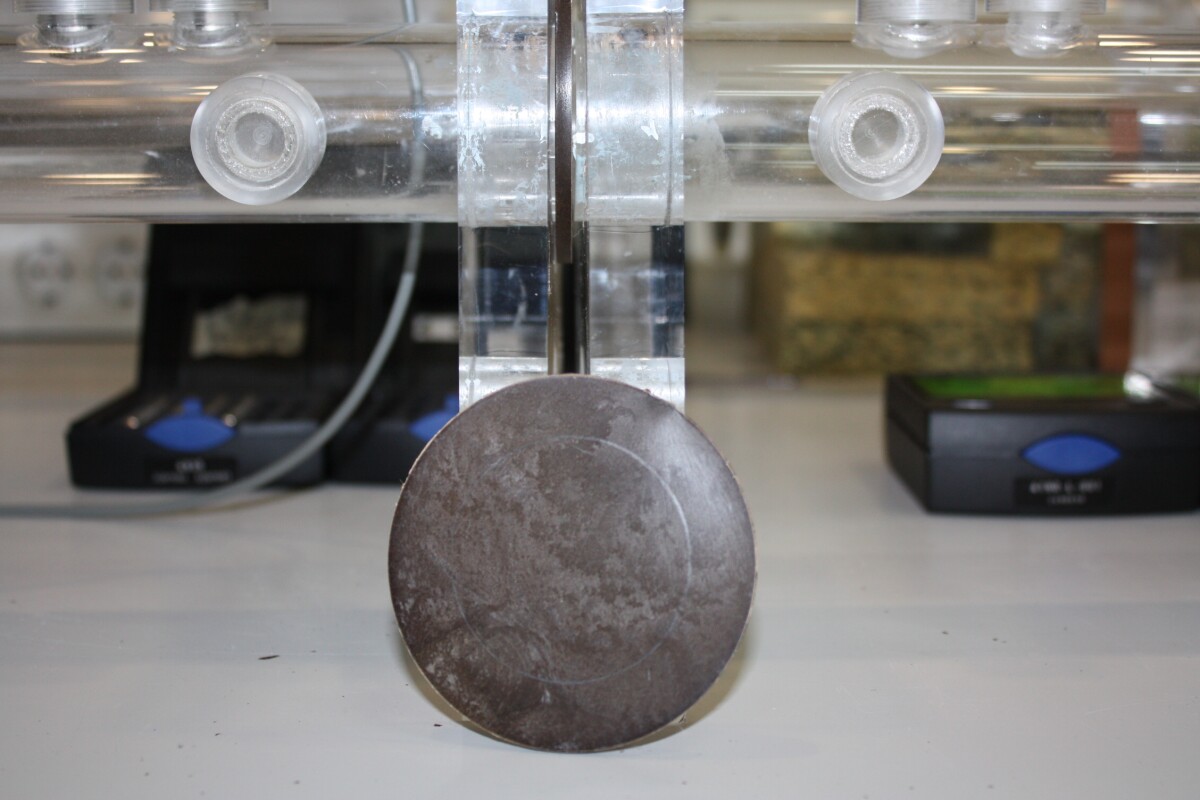

The new boards are created from orange tree trimmings, which are collected from the fields and put through a defibration (or "digestion") process, before being combined with polypropylene, a common plastic found in a wide variety of products, including toys and automobile parts.

"The mechanical properties are better than those of gypsum boards; this means that with the same board thickness, the acoustic insulation is higher; or that we can reduce the thickness to obtain the same insulation", says Dr Jesús Alba, a researcher at the Campus de Gandia of the Universitat Politècnica de València, who has teamed up with researchers at the Universitat de Girona.

The "recycled" boards have an acoustic insulation potential of about 29 dBA, which is a difference of 2 dBA (or a 50 percent improvement) on conventional laminated gypsum boards, which are usually rated at 27 dBA.

"If we use a double solution material, that is, a material that incorporates two boards and an absorbent wool in between, like a sandwich, the improvement is about 5 or 6 dBA, which means it will insulate more than double the conventional system," says Dr Alba.

Alba says the new insulation boards also meet the objectives of the European research programme Horizon 2020, which focuses on replacing materials that can damage the environment with natural or recycled raw materials.

While some companies have shown interest in the product, it is still too early to determine if or when it will be commercially available. Alba says that companies will need to assess costs and look at ways of automating the production processes.

The team is working on improving the compositions to further increase their insulation properties, and is also working with ground olive stones in a similar way to the orange trimmings, having achieved very promising preliminary results.

Both Dr. Alba and Dr. Mutjé say that using agricultural sub-products, such as the waste from orange tree pruning and olive stones, could provide significant economic benefits for the industry.

The research was published in the Journal of Construction and Building Materials.

Source: Asociación RUVID