A research team from the University of Waterloo has synthesized a prototype of a lithium-sulphur rechargeable battery that, thanks to its peculiar nanoscale structure, can store three times the power of a conventional lithium-ion battery in the same volume while being significantly lighter and potentially cheaper to manufacture.

When it comes to reducing our carbon footprint, a clean, long-lasting rechargeable battery could have enormous benefits in a wide range of applications, from efficient energy storage to clean transportation.

The challenges posed by lithium-sulfur batteries

As with lithium-ion technology, lithium-sulfur batteries store the electrical charge in one electrode during the charging phase and release it to the other during the discharge phase. However, the different atomic structure of the materials involved means the reversible chemical reactions needed are quite different and harder to obtain.

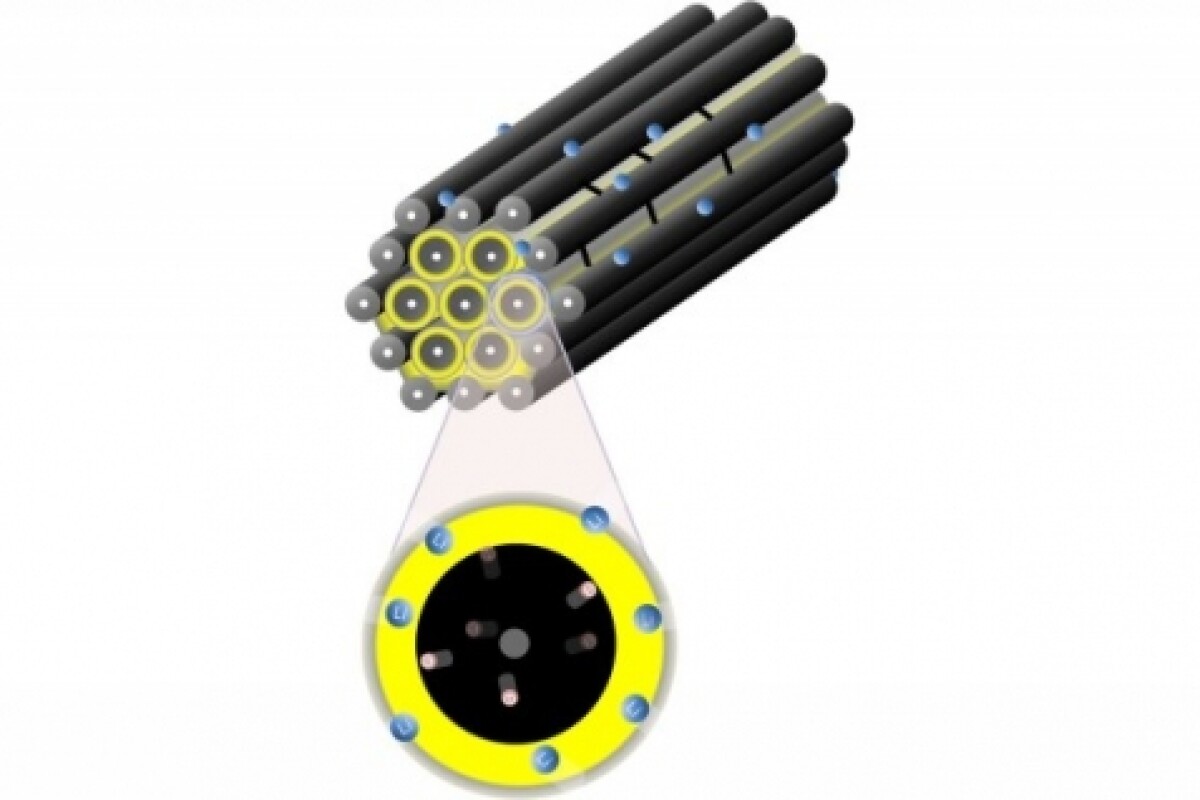

In particular, to gain high performance sulphur needs to remain in intimate contact with a conductor, such as carbon. Nazar's team tackled the issue at the nanoscale level by employing mesoporous carbon, a material that presents a highly uniform pore structure at nanoscale level.

The team assembled a nanostructure of carbon rods separated by empty channels, sulfur was then melted to fill the tiny voids thanks to capillary forces. All the spaces were uniformly filled with sulfur, thus maximizing the surface area in direct contact with carbon and boosting battery efficiency.

Advantages and disadvantages of lithium-sulfur cells

Successfully combining lithium and sulfur delivers much higher energy densities while reducing the cost of the materials used. According to internal testing, the composite material synthesized by Nazar's team can supply as much as 84 percent of the theoretical capacity of sulphur - three times the energy density of lithium transition cathodes. This should account for significantly more efficient batteries which will be lighter as well.

How much lighter? "We estimate the energy density of our cells to be about 1200 Wh/kg, for just the positive electrode, which would put the energy density of the cell at about 500 Wh/kg or more, but this depends on the other components of the cell," Dr. Nazar told us via email. "That is about a factor of 3 to 5 times more than a conventional lithium-ion battery. However, capacity fading can be more of an issue, along with lower volumetric energy and those need to be tackled more fully."

When asked whether lithium-sulfur batteries could have drawbacks at all compared to lithium-ion batteries, particularly in terms of safety, Dr. Nazar told us that because lithium-sulfur batteries typically employ a negative electrode comprised of metallic lithium, there could be safety concerns if the electrode is not adequately protected by a passivating layer. However, the research team seems optimistic that this won't be impossible to overcome: "Others have developed such technology for negative electrode protection, and also for advanced separators which should diminish these concerns. We are not in a position to judge how effective this technology is on long-term cycling, but we are certainly hopeful."

Finally, with regard to production costs, Dr. Nazar told us that, while the material themselves are certainly cheaper than those employed in lithium-ion batteries, it would be hard to quantify how much cheaper lithium-sulfur batteries will be. "Clearly the basic raw materials for the positive electrode (sulfur and carbon) are very inexpensive, but there are costs associated with processing, electrolyte, fabrication, etc that are highly dependent on the optimization of the materials and the battery configuration."