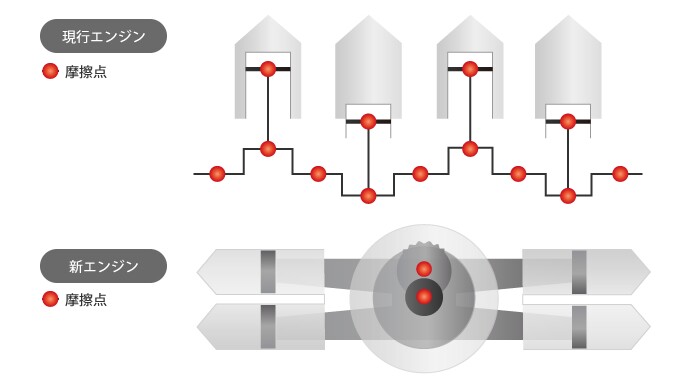

One of the many challenges facing engine designers is the need to increase power output while simultaneously retaining or improving efficiency. Although a four-cylinder engine is still an engineering marvel, there remain many friction points that reduce energy output. Namikoshi Electronics of Japan believes its unorthodox 4-in-1 concept engine could provide an alternative powerplant to the automobile industry.

Over the past few years we’ve seen alternative combustion engines in various forms, from Duke Engines radical radial design to Volvo's450 hp triple-turbocharged four-banger. Now Namikoshi's low-friction engine is getting its turn in the limelight.

Initially designed as an electrical generator, Namikoshi realized that its 4-in-1 engine could possibly be adapted for use in the automotive sector. While it's laid out in a similar way to an opposing 4-cylinder found in any old VW or Porsche, Namikoshi Electronics’ 4-in-1 engine departs from convention by virtue of a big central unit surrounded by ball bearings, a central rod and a planetary gear.

Namikoshi claims that the design has significant advantages over traditional engines in terms of friction and vibration. Whereas four-stroke engines use lubricated friction bearings in the crankshaft, connecting rods and piston pins, Namikoshi’s engine has mounted opposing pistons onto a reciprocating hub that use ball bearings, thereby reducing friction.

And unlike the traditional engine where pistons are connected in-line to the crankshaft, Namikoshi has fixed the opposing pistons onto one central unit. The result enables the 4-in-1 engine’s connecting rods too move back and forth in parallel. Namikoshi claims this approach reduces vibration and the number of friction points when compared to a typical 4-cylinder engine, producing vibration levels similar to that of a rotary engine.

In the video below, you’ll see that instead of the pistons moving back and forth individually, they work in tandem. Namikoshi says this fixed design allows the engine to more efficiently "feed" off the opposing piston’s forces and removes energy-wasting mechanical linkages from the equation.

The Namikoshi concept engine weighs in at roughly 90 kg (198 lb), has a cubic capacity of 1,500 cc and measures approximately 800 mm (31.5 in) wide by 500 mm (19.7 in) deep and 250 mm (9.8 in) tall. Bore diameter is shown as 62 mm (2.4 in), while stroke for each piston is set at 125 mm (4.9 in).

If the 4-in-1 concept engine were to make it to market, Namikoshi believes it could significantly help to reduce emissions as outputs would be on par with that of a hybrid engine. However at this stage the company has not provided output specs or friction efficiencies relative to a traditional four-cylinder to back up the claim.

Beyond the automobile, Namikoshi sees applications for the design, with alterations, in scenarios such as heating water from waste heat in geothermal systems.

The following video shows a display test of Namikoshi’s 4-in-1 concept engine.

Source: Namikoshi Electronics (Japanese)