Back in 2012, Gizmag looked at LiquidPiston’s X2 rotary engine. The compact, low-vibration, high-efficiency 70 bhp and 40 bhp compression ignition engine was something of a sensation. Now the company is back with the 70 cc X Mini engine, which LiquidPiston’s President and Co-Founder, Dr Alexander Shkolnik unveiled on Wednesday at the SAE International/JSAE 2014 Small Engine Technology Conference in Pisa, Italy.

In a telephone interview with Gizmag, Shkolnik tells us that the decision to concentrate on smaller engines was based on public feedback and that over the past two years, LiquidPiston has been improving this technology. He says that the power-dense rotary four-stroke engine prototype’s basic architecture is pretty much the same as that of the X2, which shows the scalability of the engines.

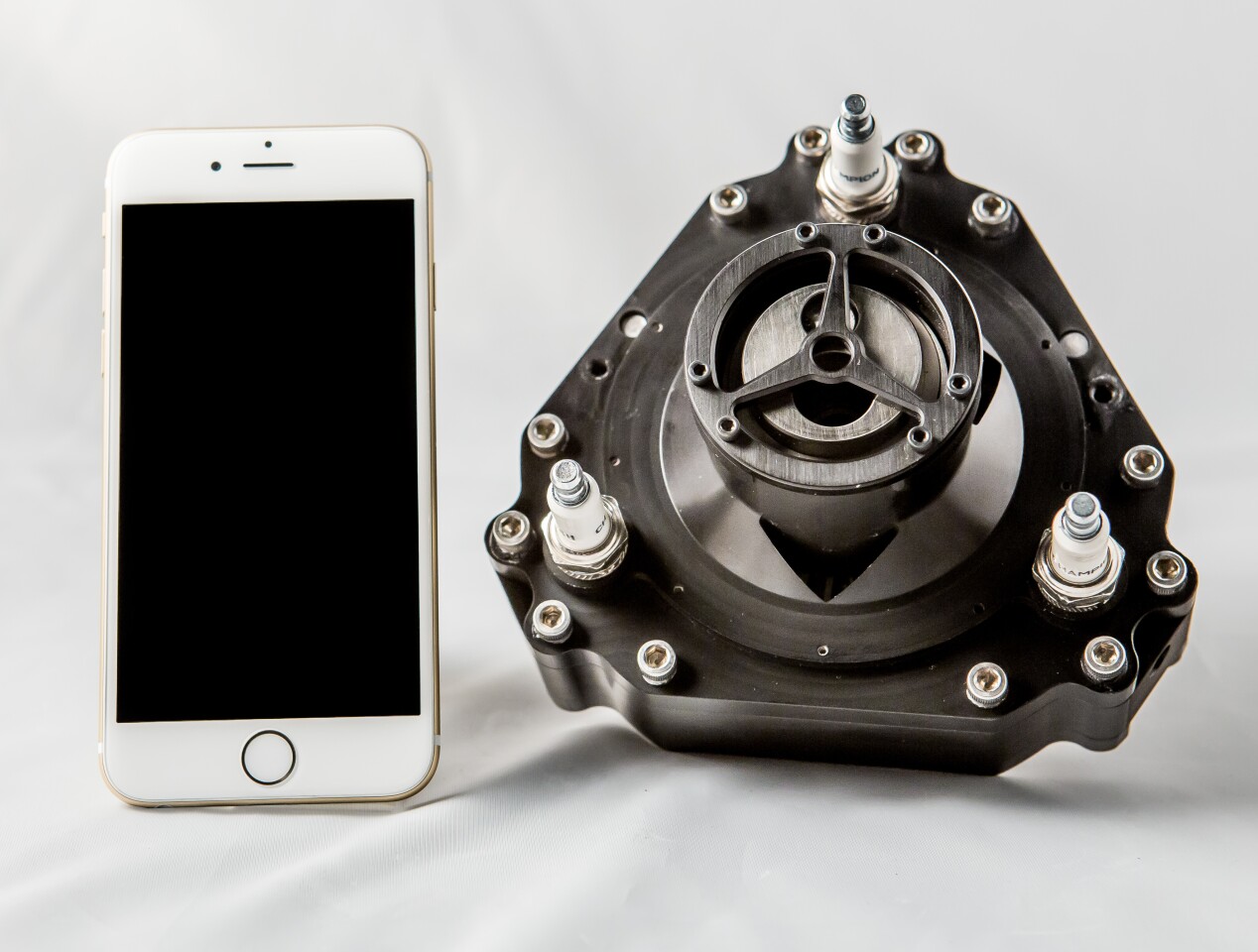

The X Mini has a 4 lb (1.8 kg) core, is 30 percent smaller and lighter than a comparable engine, fits in a 6.6 in x 6.2 in x 5.4 in (16.7 x 15.7 x 13.7 cm) box, and has only two moving parts. According to Shkolnik, the X Mini is spark ignited because it suits a petrol engine of this size better than compression ignition used in the X2. Despite its size, the X Mini puts out 3.5 bhp and when fully developed could punch 5 bhp with a weight of only 3 lb (1.3 kg).

Shkolnik says that despite its size, the X Mini has improved noise, vibration and harshness (NVH) properties. It's extremely quiet due to its lack of poppet valves and its use of three chambers versus cylinders which means that vibrations cancel one another out, and the overexpansion cycle of the combination Otto, Diesel, Rankine, and Atkinson principles contribute to the lack of noise.

LiquidPiston sees the X Mini as having a wide range of applications. Its main focus is handheld power gear, such as lawn and garden equipment, but it can also be applied to portable generators, mopeds, unmanned aerial vehicles, robots, as a range extender for hybrids, and as an auxiliary power system for other vehicles.

Shkolnik says that the X Mini’s next development cycle will focus on emissions and the company expects it to be much cleaner than similar power plants. In addition, early next year, LiquidPiston will offer a cash prize for the best ideas for employing the new technology.

"We are currently in discussions with interested industry partners looking to enhance their existing product lines," reveals Shkolnik. "The X Mini is an incredible breakthrough, and we expect to further optimize the engine for increased power (greater than 5 horsepower) and efficiency, and even lower operational noise."

According to Shkolnik, the X Mini could be on the market in two or three years.

LiquidPiston’s paper Development of a Small Rotary SI/CI Combustion Engine is available at SAE International.

Source: LiquidPiston (PDF)