Shampoo, ketchup, liquid soap, dishwashing liquid – they all come in bottles made from the same kind of plastic, polypropylene, and they're all infamous for being extremely difficult to empty. The last dregs just don't want to come out. Some of us try to squeeze the last drops out by adding a bit of water and turning the bottle upside down, but now Ohio State researchers have devised a better solution: a microscopic lining that lets the products slide right off.

The patent-pending technology promises to not only reduce that niggling frustration but also to make the plastic more durable and reusable.

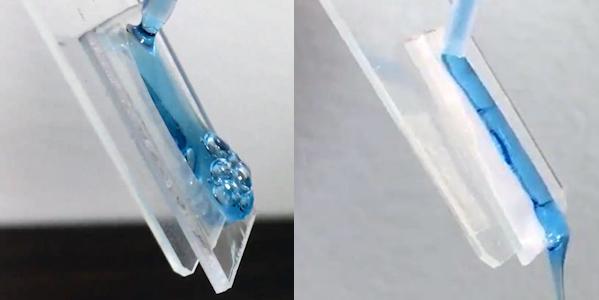

It works by creating a repellant buffer between the plastic – which soapy molecules tend to stick to – and the liquid. The coating consists of microscopic y-shaped structures, which themselves are made up of silica nanoparticles. The branches of the "y" overhangs reduce surface tension by providing a cushion of air together with stiff angles too steep for droplets to stick to the plastic, and consequently soap and other kinds of droplets slide smoothly off the surface.

This is similar to a hydrophobic coating announced in 2013 for industrial and waste management use by Florida-based containment provider Ultra-tech. But Ultra-tech's coating uses a cocktail of chemicals that make it unsuitable for food containers, whereas the Ohio State researchers' technique is environmentally friendly – it only adds silica, which is often used in small quantities in tap water and naturally occurs in many foods.

The new coating could also aid in recycling, as it makes the bottles easier to clean, and in biomedical devices, catheters, and other plastic products that need to stay clean. The researchers have successfully applied the technique to a different kind of plastic, too – polycarbonate, which is used in corrective lenses, optical media, roofing, smartphone cases, and many other products.

A paper describing the technology was published in the journal Philosophical Transactions of the Royal Society.

Source: Ohio State University