Electrical engineer Gary Krysztopik has been driving his self-built, open-framed, three-wheeled electric "hotrod" on the roads and highways of San Antonio (TX) for over three years now, but folks still can't help staring as he zooms past. While also working on gas-to-electric conversions (including a VW Bug and a Porsche Carrera), he's been busy refining and tweaking the design for his "battery box on wheels" and is now preparing to release the EZ-EV car as open source plans, build-it-yourself kits and complete vehicles.

The original Z Wheelz 2-seat Custom (ZW2C) has a bottom frame that's little more than a long battery box containing 24 deep cycle lead-acid batteries, and features a MES-DEA 200-250 AC induction electric motor driving a belt to the rear wheel and a built-in computer with GPS functionality that displays system status information. There's a roll cage with a Honda Fit windshield, a shifter for park/reverse/drive/economy mode, a parking brake, and a composite rear fender. It has a maximum range of 100 miles (160 km) and is capable of speeds of over 60 mph (96 km/h).

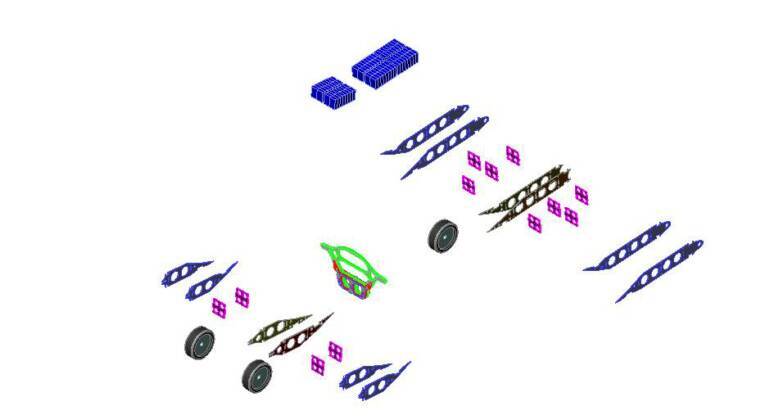

Krysztopik's new design retains the central battery box but the frame of the two-seater EZ-EV is to be made from advanced honeycombed composites (fiber glass) instead of steel. The 32 kWh battery pack will consist of 96 lithium batteries and the vehicle will have power steering, disc brakes and modern suspension. There won't be any of the modern conveniences that most of us take for granted but the design could be modified to include a variety of comfort options.

Fully assembled vehicles will be made available, but the main goal of the EZ-EV project is to make the 1,500 pound (680 kg) street-legal, highway-capable vehicle available as a kit that can be assembled by one person in a garage with standard tools in just one week. Open source plans and a parts list will also be released for those who want to build an EZ-EV from scratch.

"The idea is to maximize off the shelf parts so someone can just buy a frame with a parts list and order everything else to bolt on," Krysztopik told Gizmag. "The Mustang II front end kits are common and come complete with brakes, steering and suspension. The seats just bolt down to the floor/battery box cover. All of the motors are cylinders with a shaft coming out, and all controllers are boxes that are bolted down to the floor. This stuff is so simple and modular, which is what makes this work so well."

According to Krysztopik, the finished EZ-EV can then be registered as a motorcycle in most states (but advises checking local laws before jumping in). He expects the vehicle to easily manage over 80 mph (128 km/h), with a range of up to 150 miles (241 km) per charge (depending on the battery/motor configuration chosen by the buyer).

Enclosed bodies are also in the works for those who would rather be surrounded by an outer shell, similar to the body mold for the Freedom Car by Jerry Dycus. The long-term aim is to have pop-on body panels that can be 3D-printed.

To help turn his electric dream into a reality, Krysztopik has hit the campaign pages of the Indiegogo crowd-funding platform. For US$1,000 backers can receive a quarter-scale EZ-EV model, $7,500 will secure a full-size frame and $10,000 will get you a rolling chassis kit. Lower reward levels are available for those who want to support the project.

"I can get this vehicle on the road in as little as six months, and I want to make quarter-scale kits like the Lego Mindstorm kits for education programs," he said. "They can build and race the scale models and then get a ride in the full size version. I'm really excited about how this can work as an educational program that is so closely tied to growing clean tech businesses."

Source: EZ-EV, Indiegogo page