While lithium-ion batteries may outperform their older, lower-tech counterparts, they do have one drawback – occasionally, they catch fire. This can happen when fern-like metal structures known as dendrites form between the battery's two electrodes, causing a short circuit. Now, however, researchers at the University of Michigan have used Kevlar nanofibers to create a barrier between the electrodes, which is impervious to those nasty dendrites.

Ordinarily within a lithium-ion battery, a very thin microperforated plastic membrane is used to separate the two electrodes. While individual lithium ions are able to pass through the pores in that membrane, electrons cannot, so they instead travel through a circuit and create an electrical current in the process.

After repeated charge/discharge cycles, the lithium ions can begin forming into dendrites on the surface of one electrode. If the pores in the separator membrane are too big, the dendrites can grow right through the plastic, ultimately reaching the other electrode. Once that happens, the electrons can pass straight through the dendrites, shorting out the circuit and causing the battery to overheat.

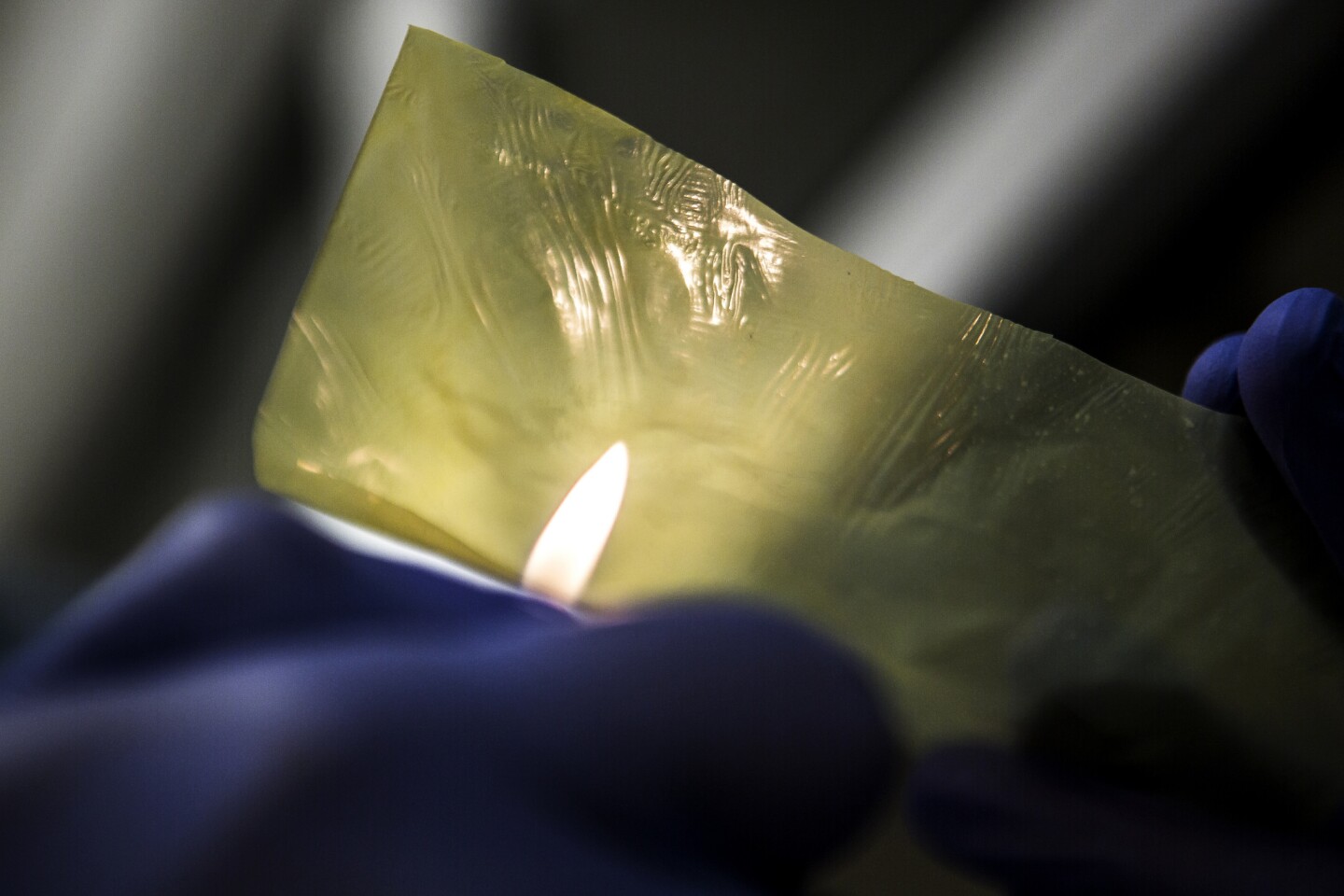

In order to remedy that problem, the U Michigan team has used layered non-conductive Kevlar nanofibers to create a membrane with much smaller pores. While regular separators have pores measuring a few hundred nanometers across, the pores in the Kevlar membrane measure just 15 to 20 nm. That's still large enough to let lithium ions through, but small enough to block the passage of a 20- to 50-nm dendrite tip.

The membranes can also be made much thinner than existing separators, thus allowing for either thinner batteries, or ones with higher energy densities. Additionally, because Kevlar is highly heat-resistant (see photo above), batteries utilizing the new membranes may be better able to withstand fires.

The university has founded a spin-off company, Elegus Technologies, to further develop and commercialize the technology. Production is expected to begin toward the end of 2016.

Source: University of Michigan