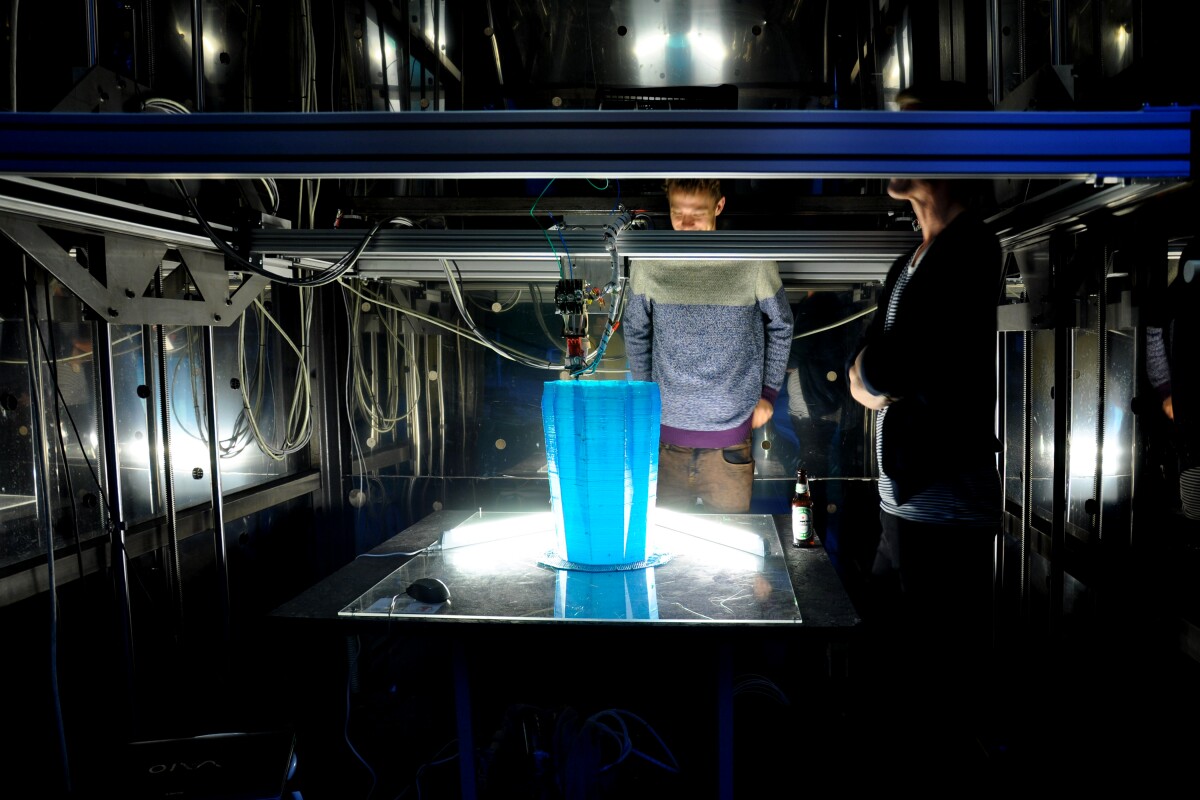

It is surely now but a matter of time before we are reporting on the completion of the first 3D-printed house, or at least something purported to be such a thing. Amsterdam-based DUS Architects is the latest company to show its hand, and has developed its own 3D printer, the 6-meter (20-foot) tall KamerMaker (literally, RoomMaker), with the intention of 3D printing a house before the end of the year.

The intention is that the KamerMaker will print building components on site. The machine can print components, fabricated from polypropylene, up to 2.2 by 2.2 by 3.5 meters (7.2 by 7.2 by 11.5 feet) in size. It's hoped that in future the KamerMaker will be able to print objects from recycled plastic.

DUS Architects has announced that it will commence construction of a 3D-printed canal house in the coming months, with completion before the end of the year. Initially, 1:20 scale components are printed and tested using the open source Ultimaker 3D printer. DUS Architects tells Gizmag that its KamerMaker is in essence a larger Ultimaker, from which 1:1 scale versions of the components will be printed for construction.

In an email to Gizmag, DUS Architects describe 3D printing as "a new craftsmanship," which the company hopes will foster local production without need of mass production. "We believe in the importance of the designing of the public domain, and nowadays that involves both the physical world and the virtual world," the company told Gizmag. "KamerMaker allows for unique, made to measure architecture, at fewer costs, with less resources, less waste material, less building transport etc."

DUS Architects chose a canal house as being a symbol of Amsterdam. The intention is that the first room to be built will be a welcoming room where visitors can come to see 3D printing in action, somewhat merging the concepts of construction and exhibition.

DUS Architects hopes to complete the 3D printed canal house in Amsterdam's Autumn. The company joins Softkill Design and Universe Architecture in its aspirations to 3D print a house. Softkill hopes its ProtoHouse 2.0 will be completed by the third quarter of this year.

Source: DUS Architects