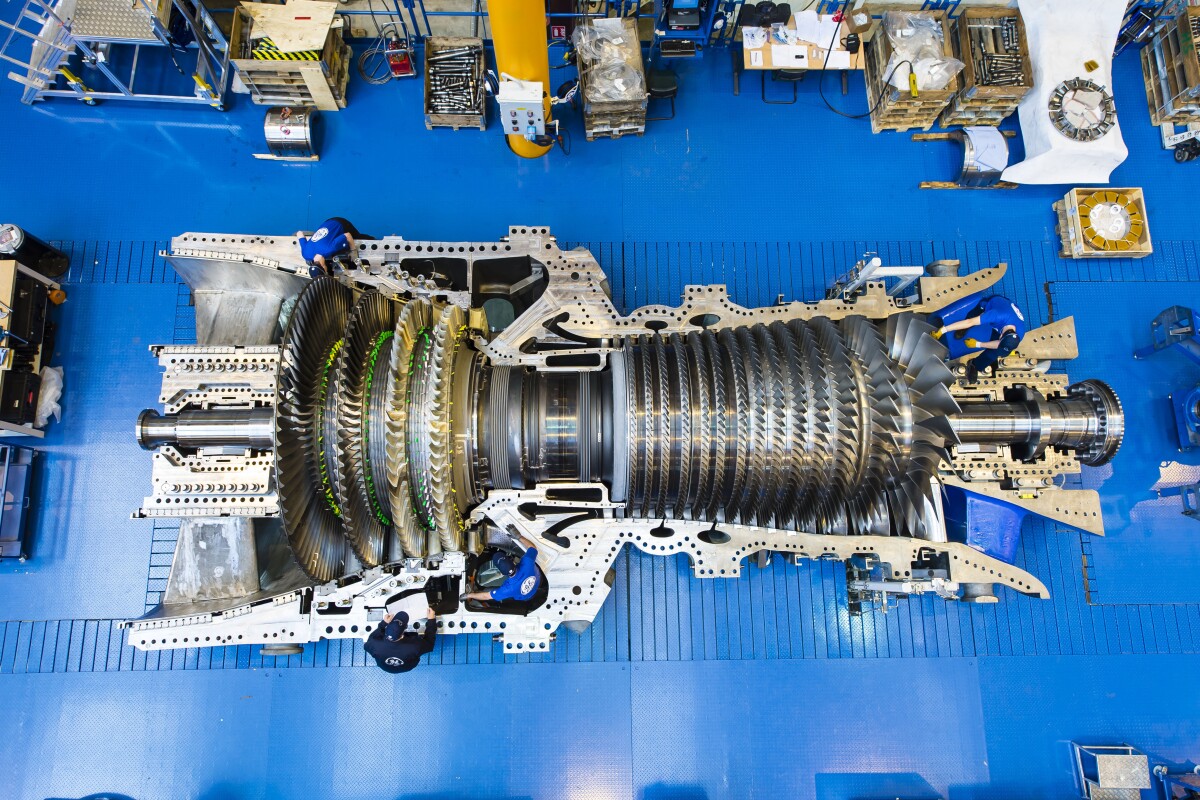

One of the problems with building the world's largest and most powerful gas turbine is that you need to build a test bed to match. Having invested US$1 billion in its 500,000 bhp 9HA Harriet gas turbine, GE had to fork over another US$185 million to build a full-load test bed at GE Power & Water in Greenville, South Carolina that can handle the grid-busting output of Harriet.

The latest of GE’s H-class turbines, when partnered with a steam generator Harriet can run a 600 megawatt steam power plant capable of supplying 600,000 homes, burns a variety of natural gases from shale gas to liquid natural gas, and instead of generating electricity, blasts out hot air at speeds of a Category 5 hurricane that could fill a Goodyear blimp in about 10 seconds.

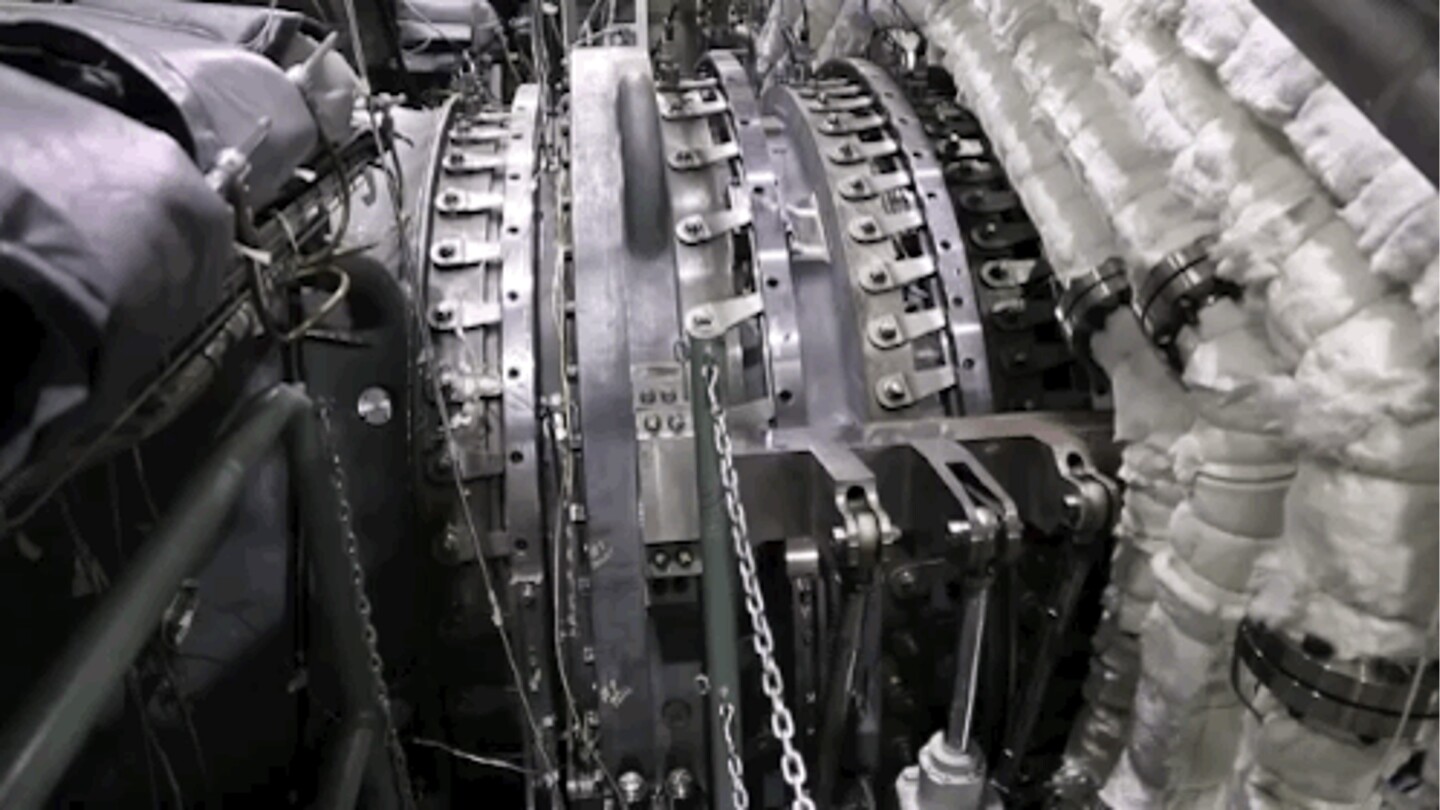

To achieve this, Harriet has superalloy monocrystal turbine blades with thermal barrier coatings capable of withstanding 2,900° F (1,600° C). It has variable stator vanes originally developed for supersonic jet engines that direct the airflow, and a modular design with blades that can be replaced individually. In addition, it's designed for automated operation, has a combined cycle efficiency of over 61 percent, and low emissions.

GE says that field testing such a monster machine has its limitations. Not only do field tests lack the extremes that the turbine might encounter, but it limits the data collected. Another problem is that the power output of Harriet can destabilize or damage the power grid during extreme testing, so it needs to be isolated. That's where the Greenville rig comes in.

The new turbine test bed not only has its own gasworks with 180,000 gallons (681,000 L) of liquefied natural gas, it also boasts North America’s largest railroad turntable to move Harriet about. According to GE, the test bed can simulate altitude and temperature conditions from hot deserts to frigid mountains.

"Here we can really see what it’s made of," says, Eric King, GE’s man in charge of the test bed. "In field testing, we measure data and extrapolate. With this test stand, we measure data and then verify it."

Testing on the French-made Harriet began in April of last year and went on for three months. During this time, engineers simulated normal operations, tested, fuel and load flexibility, and subjected the turbine to overloading outside specifications with extreme events, such as oversupplying the grid with power.

While this was going on, 5,000 instruments and sensors on Harriet and another 2,000 on the test bed collected 5 TB of data and ran it through a bespoke software suite. GE says that this shaved a year off the development cycle, and that the data will be used to aid future development, as well as fine tune the turbine, of which 15 are on order in the United States, Europe, and Japan.

The video below discusses the 9HA Harriet and its testing.

Source: GE