The University of Delft has a program devoted to kite-based generation systems, with 20 years of research and development under their belt since Wubbo Ockels, the first Dutch astronaut, established it. Now, members of the team are exploring practical niches where kite-based power might pay off. One has just completed a trip through Kenya, Tanzania and Senegal seeking opportunities for kite generation in rural Africa.

Christopher Grete, a member of the Delft KitePower curriculum focusing on deployment of kite generation, has just returned from an extended trip through Africa where he was drumming up interest in using kite-based generation in rural Africa. This is an area typically poorly served by the national grids and with significant logistical challenges for major construction. Delft has been researching kite-based generation since 1993 when the first Dutch astronaut into space, Wubbo Ockels, established the program. The faculty has several professors and students engaged in simulating, prototyping and assessing all aspects of the field, but are just starting to seriously consider commercialization.

Innovative wind generation systems have a tendency to focus on the technology instead of a target business niche, and the Delft team is no exception. They have advanced three different types of kites over the years, including inflated tube kites similar to those used by kite surfers, inflated airplane-style kites and airfoil kites.

They have stayed with fabric kites which typically have an advantage for deployment, crashes and recovery of airborne generation while giving up top-end power to rigid wings. The inflated and airplane kites they use have greater speed and hence power advantages over airfoils, but of course depend on either ground-based repressurizing, or as yet unbuilt airborne repressurization systems. This is a similar challenge to their counterparts at TwingTec, who use a unique, inflated structural member of high-strength.

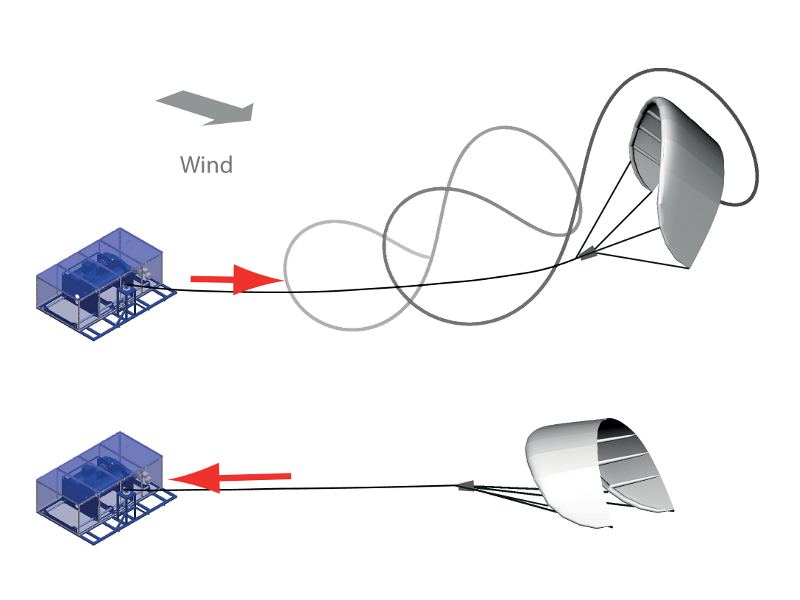

The Delft staff have tried a mixture of control systems over the years. For some of their prototypes they have used radio controls, while for others they use ground-based tether controls just as any traction- or stunt-kiter is familiar with. They have settled on an airborne, radio-controlled system positioned in the bridle of the kite that hauls in and releases the control tethers for the kites using microwinches. This increases airborne complexity, but eliminates multiple lines running all the way to the ground and multiple ground winches for control. It also allows easy depowering of the kite for the upwind pull. This is a very reasonable compromise, and the solution allows intelligence of automated control to be ground-based or in the control unit itself in the future.

At present, they are flying their kites manually with a ground-based pilot and winch operator team, but this is an area that they are focusing on automating. It's also an area where they are behind the front runners in this space, Makani and SkySails. Both of those companies have built automated launch, flight and recovery systems that are robust and work today, Makani for its hard-body wing, and SkySails for their cargo-ship towing airfoils.

Because of their airborne control system, their ground station is relatively simple, with a single winch. What's missing is a roost mechanism for automated launch and return of the kite to the ground station. This is necessary for both very high and very low wind scenarios which will occur, and the lack of attention to this to date is indicative that they have been focused on research into specific areas of kite energy rather than into creating a commercial system. SkySails has this solved for fabric kites with their proven commercial solution today.

Onshore high-altitude wind rapidly runs into problems with flying effectively invisible cables potentially kilometres long into airspace where small planes and helicopters fly. And it rapidly runs into problems with downwind ranges in the event of a failure situation which might drape very thin but very strong cables over power lines, roads and buildings. Delft's soft-structure kites virtually eliminate danger from the kite itself if the cable snaps, but overall potential liability is higher compared to alternatives, which is why most high-altitude companies looking to commercialize target offshore or niche remote situations.

That's where Christoph Grete's recent trip comes in. He traveled to the capitals and countryside of Kenya, Tanzania and Senegal on the coasts of Africa. He met with governmental agencies, research institutions, university departments and companies engaged in power in Africa. He experienced several power outages even in the developed parts of the countries, and heard clearly that many rural areas were completely disconnected from the national grid and dependent on fossil fuels that were trucked in to generators at substantial expense. Small-scale renewables in these circumstances can have very advantageous price points for specific areas and applications. One suggestion was providing power for long-lasting UHT-milk processing, a virtuous combination.

Rural Africa has large spaces and low existing technical infrastructure and air traffic to disrupt. This makes a potential siting of kite power have lower concerns. However, the combination also increases the challenges of getting more complex technical and electronic equipment serviced. He has identified several research and deployment opportunities for the Delft technology and is working to get them funded and moving forward to address concerns.

It's possible that at least some of Africa's next wave of rural electricity will come from the sky.

Source: Delft University of Technology