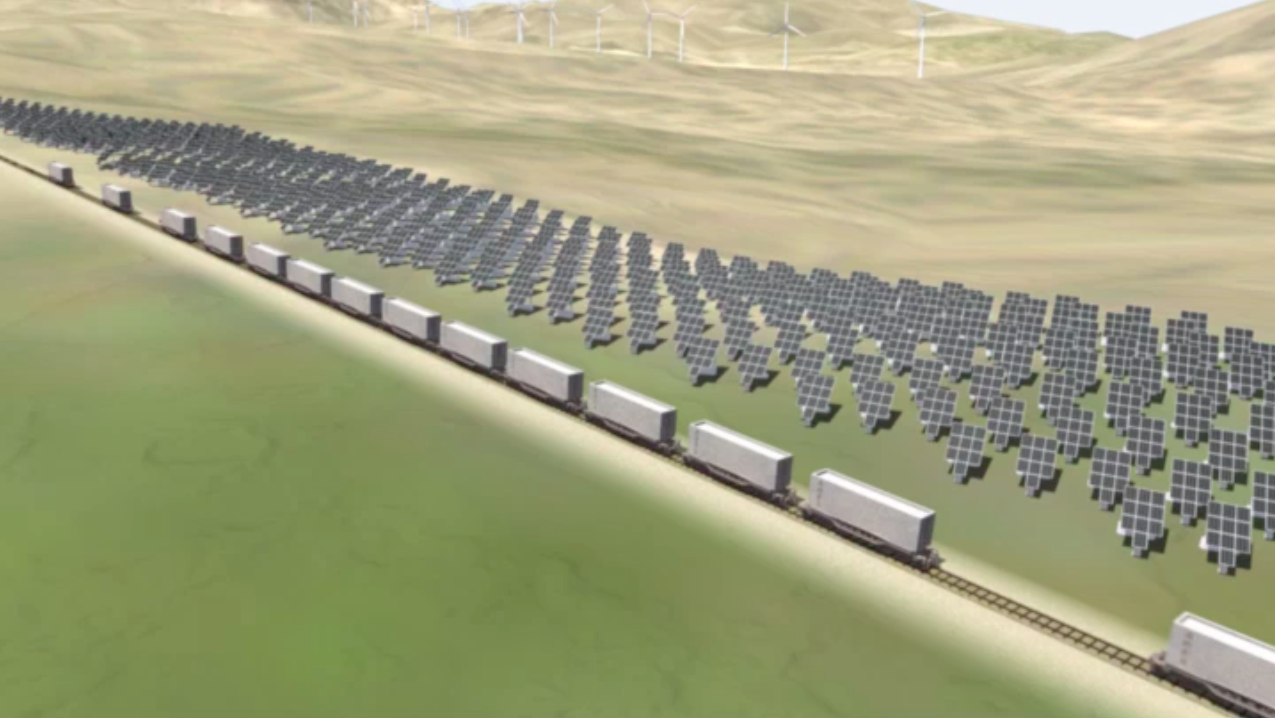

We’ve recently looked at ocean-based energy storage system concepts from MIT and Subhydro AS that are designed to overcome the intermittency problems of renewable energy sources like wind and solar by pumping water out of large tanks and using gravity to let it back in and generate electricity when needed. Santa Barbara, California-based company Advanced Rail Energy Storage (ARES) has come up with a land-based alternative that would provide grid scale energy storage using electric locomotives.

ARES’ technology uses heavy rail cars that are pushed to the top of a grade using excess power from renewable energy plants or when electricity demand is low. Then, when the wind drops, the sun stops shining, or electricity demand rises, the rail cars are released back down the hill, generating electricity through regenerative braking.

Because the system doesn’t rely on the use of water like the aforementioned ocean-based systems, the company says the technology is suitable for a wider variety of areas with minimal environmental impact. The company says the system can also respond to increases or decreases in demand in a matter of seconds, boasts a charge/discharge efficiency of 86 percent, and can deliver constant power for periods of up to eight hours.

ARES’ Director of Technology Development, William Peitzke told us to think of the system as basically a “grid-scale flywheel or battery, but one which is able to lock into direct synchronization with the grid providing heavy inertia for added grid stability.”

The company says its system is scalable and can be configured to provide grid-frequency regulation systems from 10 to 200 MW power and grid scale energy storage systems from 200 MW power with 1 GWh of energy storage, up to regional energy storage hubs of 2 GW power and 32 GWh of energy storage. ARES adds that its system also boasts a higher energy-to-power ratio than flywheels, a lower life-cycle cost than batteries and a faster ramp-up rate than pumped-storage.

With multiple vehicles position on the same track, the vehicles move independently and can be positioned mid-elevation in a queue. As one vehicle comes out of the queue at the end, another enters the queue to maintain a constant power into or out of the grid.

Power is transferred to and from the vehicles by way of a conductor rail, while vehicle speed and location information gathered from small leading wheels on the vehicles is transmitted to a control station that coordinates the vehicles based on current energy requirements and prevents the vehicles from crashing into each other. In the event of a power disruption, air brakes on the vehicles activate automatically.

ARES recently held an open day at its R & D facility located in Tehachapi, California. Built as a proof of concept for its patented Regulation Energy Management (REM) system, the pilot plant is designed to even out intermittent power supply from a neighboring wind farm. This facility features a pilot vehicle that weighs 12,500 lb (5,670 kg) and runs on a 15-inch (381 mm) gauge track that is 880 ft (268 m) in length, making it 3.75:1 scale when measured against a standard 4 ft 8.5 inch (1,435 mm) gauge track.

The company is currently in the middle of the permit process to construct a full-scale commercial 50 MW REM system in Pahrump, Nevada for the Valley Electric Association and the California Independent System Operator (CA-ISO). This system will extend the length of the track to 5 miles (8 km) and up the weight of the individual vehicles to 300 tons (272 tonnes). The single track will be on an eight percent grade and have 32 vehicles operating on it, each able to absorb or provide around 1.5 MW of power.

ARES CEO Jim Kelly adds that the system can "be deployed at around half the cost of other available storage technologies. Just as important, ARES produces no emissions, burns no fuel, requires no water, does not use environmentally troublesome materials and sits very lightly on the land.”

The following video illustrates how ARES’ REM system coordinates multiple vehicles on a single track to deal with intermittent power supply.

Source: ARES