The 3D printer industry is growing in both the professional and maker markets. With more and more 3D printers diving under the US$4,000 price-point, is it time for you to pick up one of your own? Though the consumer end of the market is still young, business is booming, and this disruptive technology is something that will definitely appeal to many Gizmag readers. That’s why we’ve taken the top desktop 3D printers and lined them up for a side-by-side comparison.

The Lineup

With so many open-source designs and readily-available 3D printers from both major corporations and Kickstarter start-ups, it would be nearly impossible to (both curate and read) create a complete list, so here are five of the most popular:

Keep in mind that this list is by no means comprehensive, these are just some of the most popular desktop 3D printers on the market. Also, many 3D printers, including many of those on our list, have modular components or open-source formats, so some of the technical statistics can be tweaked and changed to user preferences, providing they have the skill and know-how to do so.

Print Area

Desktop 3D printers have been somewhat limited when it comes to a print area, since the printer needs to, ideally, fit on your desktop. The LulzBot TAZ has claimed the largest print area for under US$5,000 for some time, and it stays true to that claim with the 3.0.

Print Volume

Like the print area, the build volume of these printers is limited to your desk space. Though the LulzBot, which Gizmag reviewed back in October, and Cube X, which is the higher-end version of the 3D Systems Cubify printer, boast the biggest envelopes, consider the amount of desk space available before assuming bigger is better.

Print Speed

The MakerBot and LulzBot boast vastly more aggressive deposition speeds than the other printers, while the UP! Mini is the slowest. When it comes to speed, you may be getting what you pay for.

Print Surface

While heated print platforms have become an industry standard, as most 3D printers use ABS material, varying materials differentiate these printers. The heated perfboard of the Afinia and UP! Mini is, basically, an electronics breadboard, but the tiny holes give the ABS material something to grab onto while being printed. The other platforms are variations on the traditional smooth plate that originated on early desktop 3D printers. While heated glass works, these platforms often require a little extra help from PET material or an ABS slurry (or both) to make prints stick properly.

Filament Size

Filament size can affect layer resolution, and in turn, the smoothness of prints. The standard filament sizes are 3 mm and 1.75 mm, so all of the printers are fairly accepting of various filaments – no need to buy brand-name.

Print Tolerance

Print tolerance determines how close your print is compared to the original computer model. This statistic is most important if you are creating complex or moving parts. If you’re just printing Yoda heads, this is more of a luxury than a necessity.

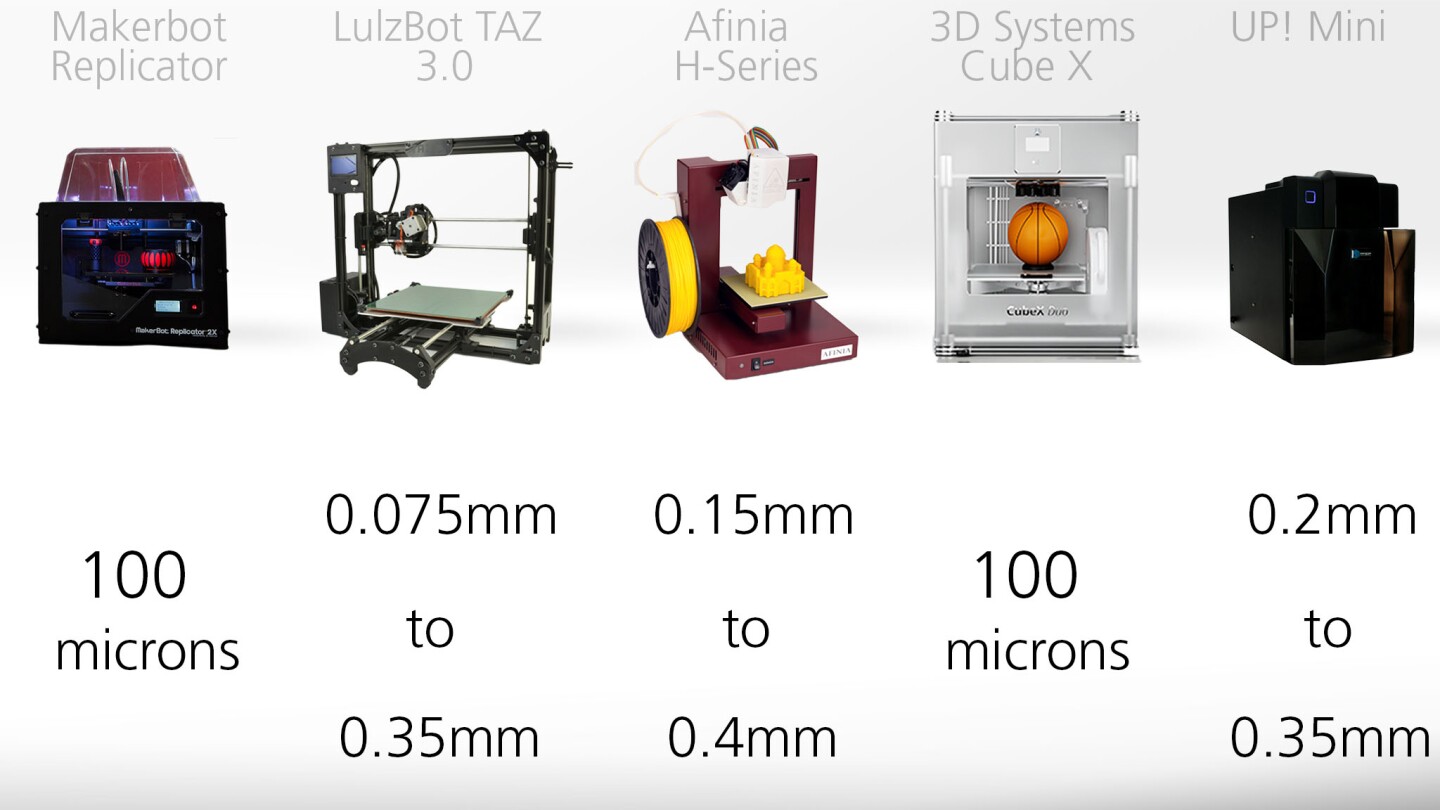

Layer Thickness

The Cube X, Replicator 2X, and the TAZ boast the best layer thicknesses, meaning they can create the highest resolution prints. If smooth, clean parts are important, smaller layer thicknesses are important, though it will take much longer to print.

Cost

Arguably, the most important statistic. The prices of 3D printers have come down drastically in the last year, and they are sure to come down more as the technology progresses. 3D printers are not perfect, and generally, you’ll get what you pay for. MakerBot’s website claims, “Patience, know-how, and a sense of adventure required.” There is still a learning curve with 3D printing, so choosing the right printer may be a tedious, drawn out venture (maybe even with some remorse).

At first, 3D printers can seem daunting and even challenging, but once you’ve spent US$1,000 or more, frustration can easily turn to motivation. Even though these few printers are just some of the most popular, they are still drastically different in their capabilities.

The next industrial revolution is upon us, might as well join in.