After extensive testing of its kinetic flywheel technology, Volvo has announced that the system can boost fuel economy by 25 percent. The company is now looking at integrating the Flywheel KERS system into its production line.

Volvo's Flywheel KERS is fitted to the rear axle. During deceleration, the braking action causes the flywheel to spin at up to 60,000 rpm. Meanwhile, the front-mounted engine shuts off. The energy stored in the spinning flywheel can then be applied via a special transmission toward acceleration or used to power the car once it reaches cruising speed.

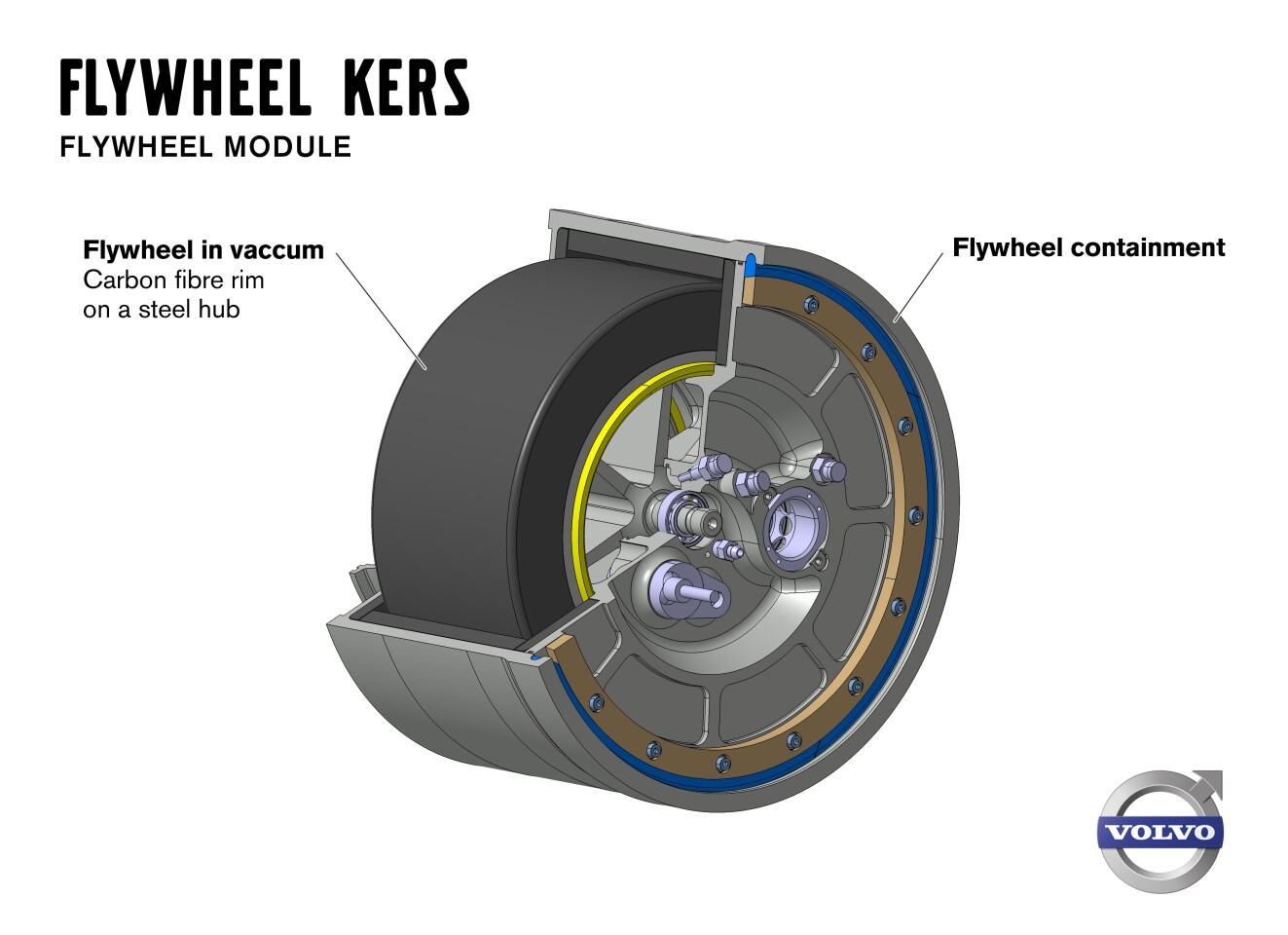

Volvo's experimental flywheel is a carbon fiber model that spins in a vacuum to minimize frictional losses. It weighs 13.2 pounds (6 kg) and measures about 8 inches (20 cm) in diameter.

During road testing with a Volvo S60 flywheel test car, Volvo found that when partnered with a four-cylinder engine, the flywheel technology offers up to a 25 percent reduction in fuel consumption versus a comparably performing turbo six-cylinder. It says that the system can also augment the engine with an 80 hp boost, giving it acceleration comparable to a six-cylinder – 0-62 mph (100 km/h) in as quick as 5.5 seconds.

"The flywheel's stored energy is sufficient to power the car for short periods. This has a major impact on fuel consumption," explained Derek Crabb, Vice President Powertrain Engineering at Volvo Car Group. "Our calculations indicate that it will be possible to turn off the combustion engine about half the time when driving according to the official New European Driving Cycle."

While the Flywheel KERS system has some clear potential, it's able to store energy only for a finite amount of time while it continues spinning. As such, it's best for driving conditions where there are frequent starts and stops. Like some hybrids and electric vehicles, Volvo's Flywheel-equipped vehicles will get the better fuel economy in the city.

"We are the first manufacturer that has applied flywheel technology to the rear axle of a car fitted with a combustion engine driving the front wheels. The next step after completing these successful tests is to evaluate how the technology can be implemented in our upcoming car models," said Crabb.

Source: Volvo