Polymer

-

Even when it’s ground into microparticles, 97% of an algae-based plastic biodegrades in compost and water in under seven months, a new study has reported. The researchers hope their plastic will eventually replace existing petroleum-based ones.

-

Researchers have developed a product that reduces hair’s moisture-absorbing tendencies, maintaining frizz-free curls for at least six hours in high-humidity environments and even allowing them to bounce back thanks to its shape-memory properties.

-

It was just this August that we heard about a super-slippery 3D-printed toilet bowl, which bacteria slide right off of. Well, if you want that same sort of functionality in your existing toilet, a special coating may do the trick.

-

Concrete may seem strong, but it can be surprisingly vulnerable to the elements. Now researchers at Drexel University have demonstrated a type of self-healing concrete embedded with “BioFibers” that use bacteria to patch up cracks as they form.

-

3D printing single objects out of different materials can be difficult, if those materials cure at different rates. The new Inkbit system addresses that problem, and has been used to print a complex functional robotic hand… in just one print job.

-

It never fails … you go to use a device that should be fully charged, but its battery has gone flat over time. Such may soon no longer be the case, however, if battery manufacturers simply start using a different type of adhesive tape.

-

Researchers have created a molecule that, when added to polymers, increases the material’s durability by making it more able to withstand temperature fluctuations. They say it could be used in everything from plastic phone cases to missiles.

-

Missing medications or not taking them as required can have costly results. Bioengineers at Rice University may have the solution to missed medications, using advanced technology to create a system that delivers time-released drugs.

-

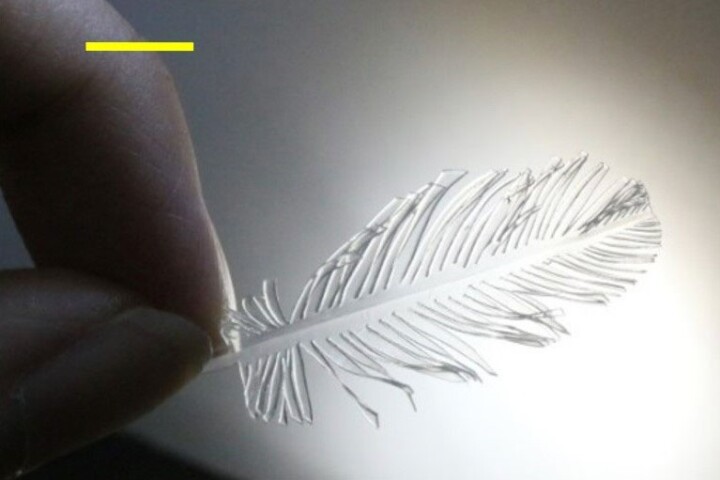

Most three-dimensional glass objects are produced via either a molding, blowing or 3D-printing process. Chinese scientists, however, have devised a technique of folding such items into shape – and it has some key advantages over other methods.

-

A versatile new material helps in the ongoing battle against corrosion. The polymer coating not only protects against corrosion, but highlights cracks as they form, automatically repairs damage to itself, and can be recycled at the end of its life.

-

A team of researchers has developed a new material that’s not only elastic, but is impervious to gases and liquids – something this kind of material is usually bad at. The material could be useful for making flexible batteries or wearable electronics.

-

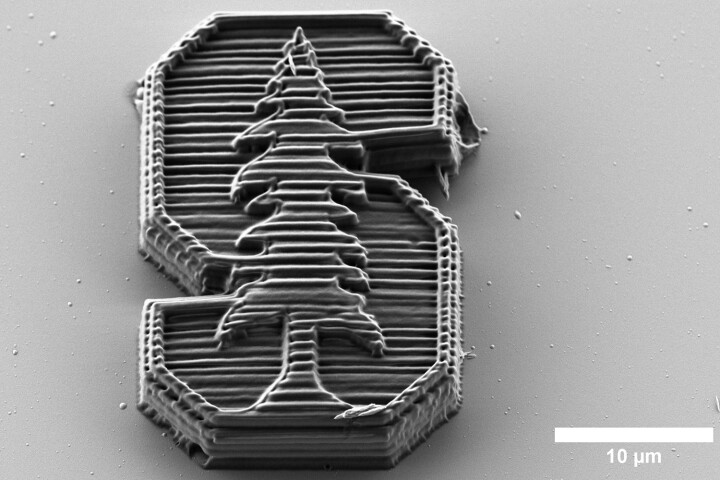

3D printing technology is used not only to build things as large as houses, but also as small as snowflakes. A new material allows the latter to be much stronger than ever before, and to be printed considerably faster.

Load More