Fraunhofer

-

An experimental new helmet could save drivers of construction vehicles from serious injuries. The device measures the extent to which its wearer is being shaken up while driving, and sounds an alert when the shaking gets to be too much.

-

An experimental new undersea robot shows great promise for use in the upkeep of offshore renewable energy platforms. Because it has the ability to climb vertical underwater surfaces – and paint them – it's known as the Crawfish.

-

Fraunhofer scientists have used ultra-thin diamond membranes to drastically cool electronic components and boost electric vehicle charging speeds, taking advantages of diamond's outstanding thermal conductivity.

-

Back in the 1970s and 80s, millions of wooden buildings were treated with preservatives that were later found to be neurotoxic and carcinogenic. A special process is now able to neutralize those chemicals, saving the structures from being gutted.

-

The search for survivors at disaster sites is one of the most commonly suggested uses for drones. If those people are buried under debris, however, they won't be visible. That's where LUCY comes in, as it could let drones locate survivors by sound.

-

If you've ever tried pulling a mussel off a rock, you'll know that they're good at holding on. The secret to their success is a natural adhesive, which has been replicated in a glue that could help keep orthopedic implants attached to bone tissue.

-

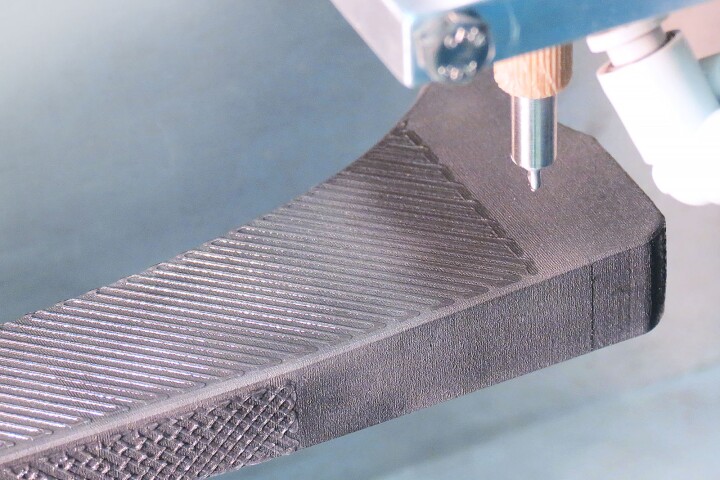

Not unlike the wings of airplanes, the blades of wind turbines need to be kept ice-free in order to function properly. Scientists have now developed an inexpensive method of using drones to apply an eco-friendly anti-icing coating to those blades.

-

When treating broken bones, doctors want new bone tissue to grow back ASAP, and they also want to keep the wound site from becoming infected. Scientists have developed an implantable composite material that reportedly delivers on both counts.

-

While there are now a number of handheld systems for checking if a medication is the genuine article or a counterfeit, most require users to access an online database. The SmartID system, on the other hand, works entirely offline.

-

Early humanoid robots probably won't be able to do much that Fraunhofer's self-balancing evoBOT can't do much faster, and its new autonomous, omnidirectional O³dyn pallet jack looks like another slam dunk for logistics and warehousing.

-

Is your scarf really made from cashmere? Is that necktie truly silk? Such questions may soon have an easy answer via a pass with your cell phone's camera thanks to a tiny near-infrared spectroscopy system developed by researchers in Germany.

-

Currently, almost all powered prosthetic hands utilize electrodes that detect the user's muscle impulses and convert them into hand movements. A new system which is in development, however, should reportedly work better by utilizing ultrasound.

Load More