Concrete

-

The production of concrete is a major contributor to worldwide CO2 emissions, however Nendo showcases a greener alternative with its Block-Wall House, which was part-built using a novel concrete that actually captures carbon-dioxide.

-

A new 3D construction printer from Icon can whip out two-story concrete buildings faster and cheaper than its previous Vulcan printer. It has already been used to build a 27-ft-high structure called Phoenix House, now on display in Austin, Texas.

-

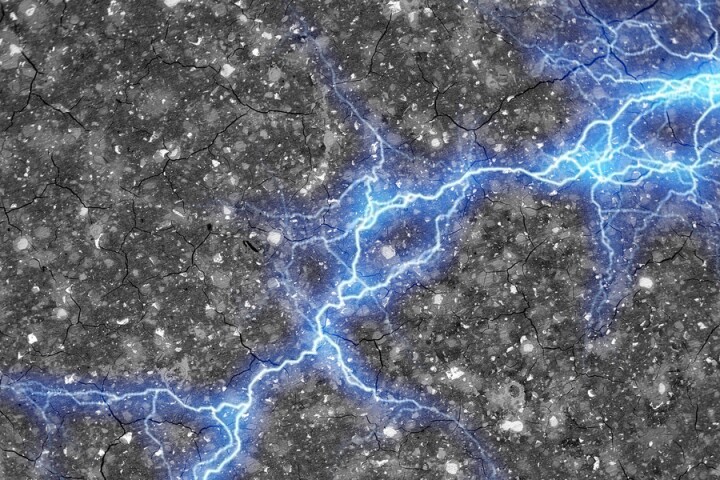

Incorporating a phase-change material into concrete, this self-heating material can melt snow and ice for up to 10 hours without any help. The novel product could reduce the need for plowing and salting and help preserve the integrity of road surfaces.

-

Thanks to our high demand for concrete, the world may eventually run out of accessible sand. Scientists at Rice University have now shown that substituting graphene can not only save sand, but makes concrete lighter, stronger and tougher.

-

Omer Arbel has unveiled a stunning family residence dubbed 75.9 that's nestled in a sprawling hayfield in the Canadian Pacific Northwest, and showcases novel monumental trumpet-shaped columns throughout its interior volumes.

-

3D-printed concrete structures are claimed to be faster and cheaper to build than their traditional counterparts, but they're not always as strong. That problem may soon be solved by adding a pinch of graphene oxide, which could also be used to detect cracks.

-

Concrete may seem strong, but it can be surprisingly vulnerable to the elements. Now researchers at Drexel University have demonstrated a type of self-healing concrete embedded with “BioFibers” that use bacteria to patch up cracks as they form.

-

According to some estimates, the generation of the heat used to produce traditional portland cement is responsible for 5% to 8% of all human-made CO2 emissions. A new substance known as C-Crete, however, is claimed to be a much greener alternative.

-

The Cliff Café juts out of a precipice to serve up some amazing views to go with its food and beverages. Designed by Trace Architecture Office, it's also joined by the striking Tower House nearby, which similarly puts the focus on the view.

-

Sublime Cement says it's ready to start scaling on the "world's cleanest cement," which meets industry performance standards relying on room-temperature electrolyzers in place of fossil-fueled furnaces, using a variety of zero-carbon input materials.

-

Researchers have made concrete 30% stronger by replacing a percentage of sand with spent coffee grounds, an organic waste produced in huge amounts that usually ends up in landfill. The method offers a greener approach to construction.

-

MIT researchers have discovered that when you mix cement and carbon black with water, the resulting concrete self-assembles into an energy-storing supercapacitor that can put out enough juice to power a home or fast-charge electric cars.

Load More