Rear derailleurs are problematic, particularly on mountain bikes. They get bent, they get gunked up, and they're exposed to the elements. While sealed hub transmissions lack these problems, not all of them have axles that are strong enough for multi-terrain use, they add revolving weight, and that weight is added in the back of the bike – not low and in the middle, where you want it. German company Pinion has developed what it claims is something better ... a sealed gearbox located adjacent to the bottom bracket.

Known as the Pinion P1.18, the device has been in development for the past seven years. It was launched commercially just last year, and recently gained attention when it appeared on an award-winning bike at the North American Handmade Bicycle Show.

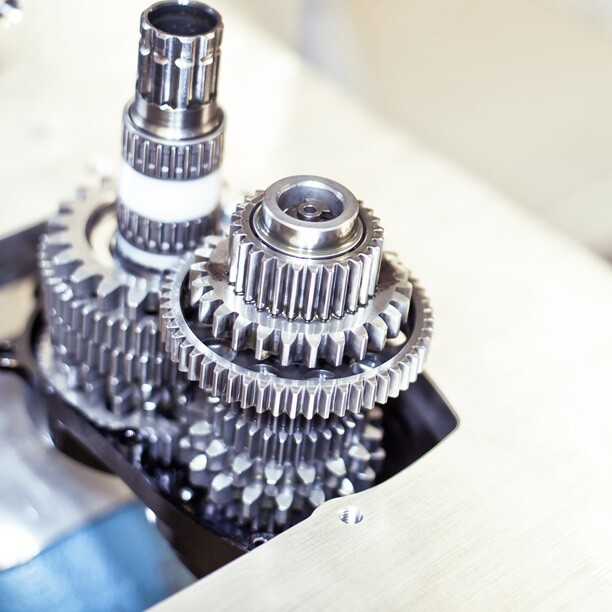

So, how does it work? Well, to quote the Pinion brochure:

"The Pinion P1.18 bicycle transmission is constructed as a spur gear with two parallel partial shaft transmissions, one with three gears, and the other with six gears. The multiplication of three by six ratios gives 18 real ratios spaced in even, ergonomically ideal, steps of 11.5 percent. The P1.18 thus achieves a total gear ratio of 636 percent."

The gears are lubricated with a 60-milliliter oil bath, that the company states should be changed once every year or 10,000 kilometers (6,214 miles) – no other maintenance is required. The gears are said to be good for at least 60,000 km (37,282 miles).

Because indexing of the shifts takes place within the box, users don't have to worry about replacing stretched shifter cables. Gear changes are activated via a SRAM-like grip shifter, are reportedly "lightning fast," and can span several gears in one shift. Additionally, they can be performed even when the cranks aren't turning.

It sounds good, but of course nothing is perfect. For one thing, the P1.18 can't simply be installed on an existing bike – the frame has to be designed around it. Additionally, the gearbox itself weighs in at around 2.7 kilograms (six pounds) – for comparison, the combined weight of a Shimano XT front and rear derailleur sits at about 384 grams (0.9 lbs).

It should be kept in mind, however, that the P1.18 makes a cassette unnecessary, plus it incorporates components such as a bottom bracket shell and axle. It also allows for the use of a belt drive instead of a chain, which plenty of folks would no doubt appreciate.

Because it can only be built into dedicated frames, the Pinion P1.18 isn't currently available to the general public. A list of manufacturers using it on their bikes can be accessed via the company link below.