Possibly the only good thing to come out of the Deepwater Horizon disaster is the subsequent increase in research into finding more effective ways to cle_n up oil spills, including such initiatives as the X PRIZE Foundation's Wendy Schmidt Oil Cleanup X CHALLENGE. Joining the list is a new method devised by researchers at MIT who propose separating oil and water using magnets. The new technique would allow the oil to be recovered to help offset the costs of the cleanup operation.

Oil isn’t magnetic, but suspending magnetic nanoparticles within the oil turns it into a magnetic liquid known as a ferrofluid. Previous research efforts using ferrofluids typically involved pumping a water-and-ferrofluid mixture through a channel with magnets on the outside directing the flow of the water one way and the flow of the ferrofluid another. However, this technique will work only if the concentration of the ferrofluid is known beforehand and remains constant – neither of which is possible in water contaminated by an oil spill.

For their approach, the MIT researchers made two modifications to the existing method. Instead of placing the magnets on the outside of the stream, they were immersed within it, and instead of being oriented parallel to the flow of the stream, they run perpendicular to it.

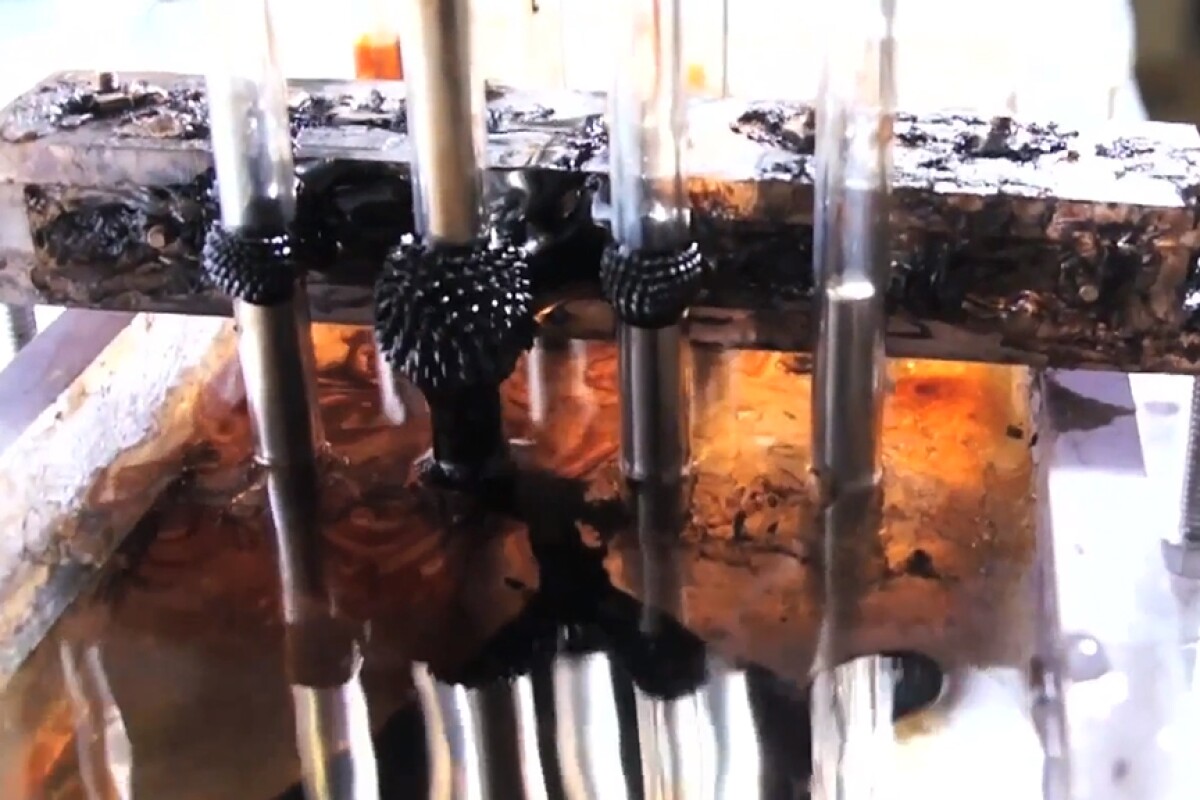

Because the magnetic field of the cylindrical permanent magnets used by the MIT team is strongest at its edges, the oil is attracted to the tips of the magnets much more strongly than the sides. And as the bottoms of the cylindrical magnets were embedded under the waterline in the base of a reservoir and the tops of the magnets were positioned above water level, the oil didn’t collect around them. Rather, it shot up the sides of the magnets to form beaded spheres at the top.

Shahriar Khushrushahi, a postdoc in MIT’s Department of Electrical Engineering and Computer Science and lead author on a paper describing the approach says the technique provides excellent separation between oil and water. Additionally, its simplicity makes it feasible for large scale manufacture and deployment at sea for days or weeks a a time, where electrical power and maintenance facilities are limited.

While the team is yet to determine the most practical way to remove the oil from the magnets in an actual oil-recovery system, in their experiments they used a Halbach array. This is a special arrangement of permanent magnets where the magnetic field on one side is augmented, while the magnetic field on the other side is canceled out to near zero. This allowed the oil in the reservoir to remain unattracted to the bottom of the array, while the oil attached to the magnets was pulled off by the top of the array.

The team says that adding magnetic nanoparticles to oil mixed with water to produce a ferrofluid aboard a ship is not a challenge. Additionally, removing the nanoparticles can be achieved using a technique known as high-gradient magnetic separation. This has been done on a small scale and would allow the recovery of both the nanoparticles and the oil.

One remaining challenge is to determine how much water gets dissolved in the oil and the best way to remove it. “To our eye, you don’t see much moisture in there, but I’m sure that there is some moisture that adheres to it,” says team member Markus Zahn. “We might have to run it through multiple cycles.”

On a commercial scale, the magnetic separation method could be used in conjunction with existing oil recovery techniques such as skimming, which would perform an initial separation. The magnetic separation technique could then be used to finish the job.

The research team will present a paper detailing their work at the 13th International Conference on magnetic Fields (ICMF13) being held in New Delhi, India, in January 2013. The team has also filed two patents on its work.

MIT researchers Zahn and Khushrushahi explain the magnetic separation technique in the video below.

Source: MIT