In a bid to help shape the inexorable march toward more efficient wind power, General Electric Power and Water is developing a new fabric-covered wind turbine blade which promises to cut the cost of wind turbine manufacture significantly, while also allowing a larger blade size, and facilitating easier transportation.

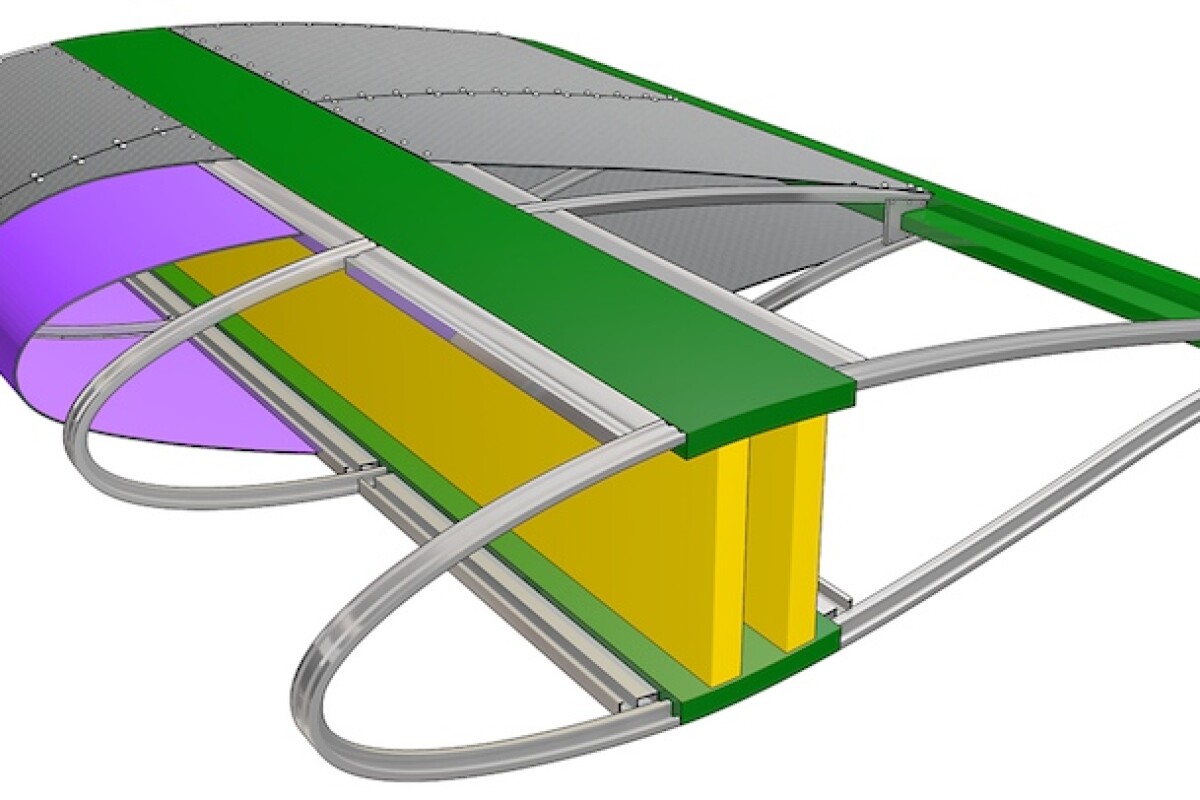

GE’s project calls for architectural fabric to be tightly wrapped around a metal space frame, to create a viable wind turbine blade. According to the company, such a design should allow for rotor diameters which exceed 120 meters (393 feet) – a feat generally not thought practical with the more widely-used fiberglass blades.

Favoring fabric over fiberglass could also ease wind turbine blade production costs by an impressive 25 to 40 percent. Indeed, GE reckons the technology will eventually allow wind turbine power to be as economical as fossil fuels, without government subsidies.

“GE’s weaving an advanced wind blade that could be the fabric of our clean energy future,” said Wendy Lin, a GE Principal Engineer and leader on the ARPA-E project. “The fabric we’re developing will be tough, flexible, and easier to assemble and maintain. It represents a clear path to making wind even more cost competitive with fossil fuels.”

Additional benefits of the fabric technology cited by GE include a 20-year lifespan, during which no regular maintenance is required, and easier transportation, with the blades perhaps assembled on-site.

GE’s proposal was one of 66 transformative energy proposals to be awarded a grant from the U.S. Department of Energy’s Advanced Research Projects Agency (ARPA-E) program, alongside groups such as MIT, Brown University, and the University of Colorado. In total, the fabric blade project received US$5.6 million, and is projected to span a total of three years development.

Though GE chose not to reveal the exact kind of architectural fabric that would be used, the company does already make rugged fabrics for wind protection and architectural design, so presumably much of the required expertise will already be in-house.

Source: General Electric via Treehugger