Reversible, temporary adhesives may not sound all that exciting to some, but to a manufacturer that needs to rapidly move small, difficult-to-handle components or a robot-builder creating a machine that can climb various surfaces, such products are the thing of dreams. Now researchers at the Max Planck Institute have created a reversible adhesive from the metal gallium that displays reversible glue-like properties that could have applications in everything from industrial electronics pick-and-place processes and short-term silicon wafer bonding, to feet for climbing robots.

Gallium is a soft, silver-colored metal that is a solid at low temperatures, and melts at 29.76° C (85.56° F), which is just above room temperature. Hold it in the palm of your hand and it will melt, and release it from your grip and it will solidify. Planck scientists took advantage of this property to create a reversible adhesive by introducing a droplet of liquid gallium in between two objects and then cooling it to below 30° C, where the gallium layer re-solidifies and the two objects stick together. To allow the adhered objects to be pulled apart, the temperature is again increased above the gallium's melting point so they can be separated with negligible force.

"Wetting an object with a metallic liquid such as gallium that forms a bond when cooled slightly is a far more gentle process for fragile materials than sucking them up using a vacuum," said Metin Sitti, Director at the Max Planck Institute for Intelligent Systems.

The Max Planck researchers see temperature-controlled gallium having distinct advantages over traditional vacuum-handling techniques. In particular, when an object is stuck to the gallium layer, the adhesive bond requires no further energy to maintain, only requiring a quick input of heat to cause it to release. The vacuum technique, on the other hand, needs constant energy to maintain suction and continue its adhesive effect.

Unlike ordinary adhesives, gallium leaves absolutely no residue behind, meaning that it can be used over and over again without ever depleting it. It also has the advantage of being electrically conductive, which may see it being used in temporary circuit connections that can be made, broken, and made again almost countless times.

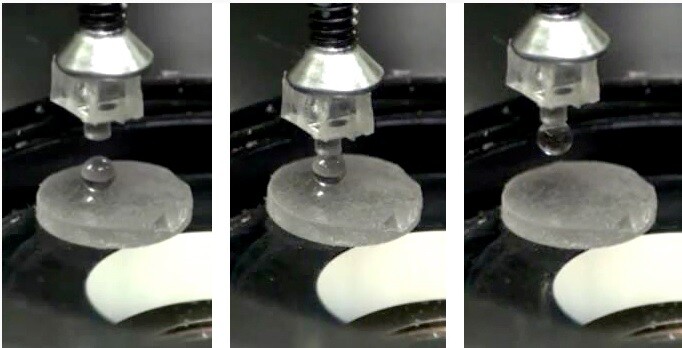

To test their theories on gallium as an adhesive, the researchers dipped the tip of a cylindrical elastomer (polymer) rod in liquid gallium, then brought it into contact with a range of materials, including glass, plastic, and gold. When this tip was then cooled to 23° C (73° F) with the aid of a peltier-effect, thermoelectric cooling device, they discovered that the solid gallium had created a robust bond connecting the elastomer and each of the tested materials.

Measurements of the adhesive strength of gallium in both liquid and solid phases was also tested.

"The behaviour of these two values tells us something about the true reversibility and switchability of the adhesion process," said Metin Sitti. "The greater the difference of the binding power between the liquid and solid state, the easier it is to reverse and switch the adhesive effect."

Gallium also worked particularly well in tests on rough surfaces and, much to the surprise of the researchers, even worked when wet. This is considered unusual for most adhesives, as adhesives that have shown powerful sticking values on rough or wet surfaces had always had poor reversibility.

"These are surface conditions that showed up as major weaknesses of reversible micro/nanostructured adhesives proposed recently," said Sitti.

As a result of its performance in these conditions, the researchers believe gallium is a perfect fit for biological uses, and Sitti envisions that it may one day be used to move individual cells, tissue samples, or even entire organs, in laboratories or hospitals.

With other possible uses in microelectronic manufacture, where a gallium-based device may more efficiently replace "pick-and-place" component siting machines, or as a possible contact-adhesive pad on the foot of a wall-climbing robot, the Max Planck team see great things – big and small – for their discovery.

"We can use it at different scales, from the nanometer range to microelectronics, and right up to larger applications," said Sitti.

For now, the team will continue exploring potential applications as well as looking at ways to optimize the technique and studying alloys of gallium with other metals, such as indium, to investigate other uses at different temperatures.

The results of this research were recently published in the journal Advanced Materials.

The video below shows a laboratory gallium adhesion test being conducted.

Source: Max Planck Institute