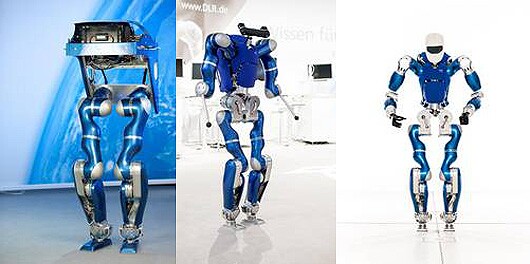

Engineers at the German Aerospace Center (DLR) have proven once again that they know how to make a snazzy looking robot. Quietly announced to little fanfare, DLR's Robotics and Mechatronics Center recently put the finishing touches on its DLR-Biped, a pair of shiny blue legs that first stepped onto the scene in 2009. Those legs have now been upgraded to the status of a full-fledged humanoid robot, sporting an all-new upper body and a new name: the Torque Controlled Humanoid Robot, or TORO for short.

"Now that the robotic body is complete, we can test processes where the robot carries out sequences of movements with foresight and fluency," explains Project Manager Christian Ott. "If a person opens a heavy door, for example, they do so in a dynamic process; they know subconsciously which moves must be performed. Our robot should be able to do this as well. Another goal is to climb stairs. This involves TORO learning how to pull itself up on a handrail like a human."

DLR's Robotics and Mechatronics Center's other major humanoid robot, Rollin' Justin, first appeared in 2008. As you may have gathered from its name, that robot moves on wheels rather than legs. Its capabilities have been gradually improved over the years, leading some to think that Justin's upper body module would be merged with DLR-Biped's legs. Instead, the team built an upper body specifically for TORO with a new head, torso, light weight arms, and simplified hands.

The researchers at DLR want to push TORO beyond what Justin and other humanoid robots like ASIMO already do, including the ability to react autonomously and intelligently in a range of different circumstances.

The DLR-Biped wasn't the DLR's first foray into walking robots, nor is it Germany's only example (the Technical University of Munich has developed two full-sized examples in Johnnie and LOLA). However, it is among an elite group of new humanoids that, like Italy's COMAN, have torque-controlled joints. These give its limbs some elasticity where prior examples were rigid and unyielding, improving safety when interacting with people and increasing robustness to unforeseen external forces.

Compared to bipeds built in Japan and Korea, the DLR-Biped was already remarkable for its very small feet. "On the one hand, we wanted to make it more difficult by using a small footprint, but on the other, it enables the robot to climb over obstacles more easily," explains Ott. Now, the team will have to tweak the robot's walking gait to incorporate its upper body weight and arm movements. Plus, the addition of arms and hands opens a world of possibilities for the team to explore.

Perhaps because TORO was only just assembled, DLR has yet to publish any cool videos starring the new robot. However, you can see an earlier incarnation of TORO (halfway between the DLR-Biped and its current form) in the video below.

Source: DLR