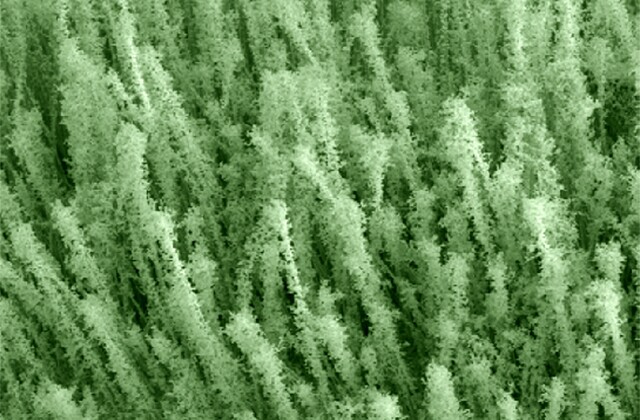

Higher-density batteries, more efficient thin-film solar cells, and better catalysts may all soon be possible, thanks to a new technique that allows nanowires to be “decorated” with nanoparticles. Using the novel technology, scientists from Stanford University have been able to festoon the outside surfaces of nanowires with intricate chains of metal oxide or noble metal nanoparticles, thereby drastically boosting the effective surface area of the nanowires. Other researchers have previously tried to achieve the same end result, but apparently never with such success.

“You can think of it like a tree. The nanowires are the trunk, very good at transporting electrons, like sap, but limited in surface area,” said assistant professor of mechanical engineering Xiaolin Zheng, who led the research. “The added nanoparticle decorations, as we call them, are like the branches and leaves, which fan out and greatly increase the surface area.”

In prior attempts by other groups, the nanoparticle coatings were reportedly too thick – the nanowires essentially just ended up being wider, without much in the way of extra surface area. The processes are also said to have taken too long.

Zheng’s process, known as the sol-flame method, is able to quickly produce multiple open tendrils of linked nanoparticles, resulting in a much higher surface area. It starts with untreated nanowires being dipped in a solvent-based metal and salt nanoparticle gel, then subsequently being allowed to air dry. Next, they’re exposed to a quick burst of flame. This burns away the solvent, and causes the remaining nanoparticles to fuse together into branch-like structures, radiating out from the nanowires’ sides.

Due to the high temperature and brief treatment time involved, the structures remain at a manageable length, and are spread evenly along the length of the nanowires. By varying the number of dippings, along with the concentration of nanoparticles within the gel, the scientists have been able to control the size and density of the structures.

“We were a little surprised by how well it worked,” Zheng said. “It performed beautifully.”

A paper on the research was recently published in the journal Nano Letters.

Source: Stanford University