Only a small percentage of backlight actually makes its way out through the multiple layers that make up the ubiquitous LCD displays we use today. That may change with the development of new filter technology at the University of Michigan. White light is sent through tiny, precisely spaced gaps on nano-thin sheets of aluminum and is said to result in brighter, higher definition color reproduction. Other benefits of the technology include efficiency gains and simpler manufacturing.

A traditional LCD display is made up of two layers of polarizers, a color filter sheet, and two layers of electrode-laced glass in addition to the liquid crystal layer. The new color filter cuts out a couple of extra layers by acting as a simultaneous polarizer. It's less than 200nm thick, and consists of a layer of Zinc Selenide sandwiched between two sheets of aluminum.

At precise intervals, tiny slits trap and transmit white backlight out through the structure. Different spacings essentially result in different wavelengths being caught. Gratings set at around 360 nanometers apart emit red light, those spaced at 270 nanometers emit green, and blue colored light comes from slits spaced about 225 nanometers apart.

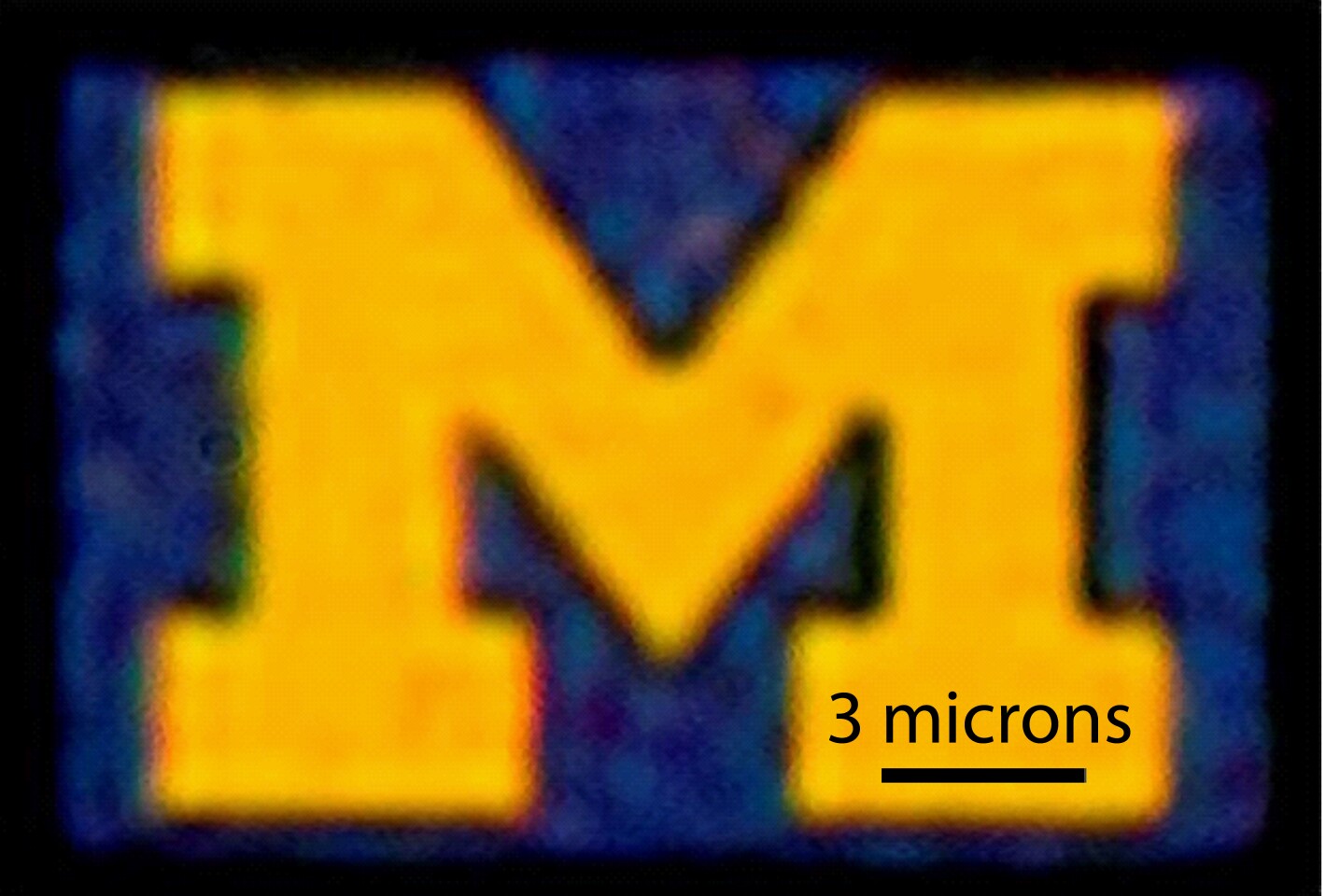

The research team, led by Jay Guo, an associate professor in University of Michigan's Department of Macromolecular Science and Engineering, used the technique to produce a tiny University logo which is about a sixth the size of a human hair at 12 x 9 microns. OK, so it looks a little blurred in the photo, but that's because it has been magnified about 5,000 times.

The pixel size produced by the new filter is around eight times smaller than those on an iPhone 4 and "about an order of magnitude smaller than those on a typical computer screen," according to Guo. "Amazingly, we found that even a few slits can already produce well-defined color, which shows its potential for extremely high-resolution display and spectral imaging." Future uses for the technology include wearable or extremely compact displays as well as monitors and projectors.

The university is currently looking at patenting the technique while the researchers look to make the technique production-ready, a task said to be made easier by the potential for simpler manufacturing processes.

Detailed information on the technology can be found in the research paper, entitled "Plasmonic nano-resonators for high resolution color filtering and spectral imaging", which has now been published in Nature Communication.