One of the great things about 3D printers is the fact that they allow anyone to become a manufacturer of small items. Unfortunately, however, they don't allow anyone to become a competent structural engineer – just because you can whip up a three-dimensional design on your computer doesn’t mean that it will translate into a sturdy physical object. That’s why researchers from Purdue University and Adobe's Advanced Technology Labs teamed up to create a program that automatically alters such designs, adding strengthening features to them before they get printed.

The program starts by running a structural analysis of a design, which identifies weak spots. It also identifies areas on the object where it’s most likely to be grasped by a user, as these regions will be subjected to extra stress.

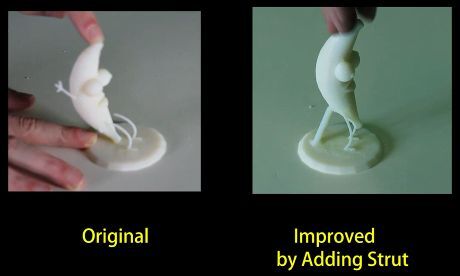

Using that information, it then chooses between one of three methods of adding strength to the finished object. These include making key structural elements thicker, adding supportive struts, or reducing stress by hollowing out elements that are too heavy.

As a result, not only is the finished product stronger, but it may also be lighter and require less material to construct. In lab tests, the team has reportedly demonstrated weight and cost savings of 80 percent.

The researchers are now looking into expanding the algorithms used in their program, to allow for the strengthening of objects with moving parts. Similar work is also being done at Harvard University, where scientists have created a program that analyzes 3D digital renderings of video game characters and figures out how to convert them into structurally-sound posable action figures.

Some examples of items made using the Purdue system can be seen in the video below.

Source: Purdue University