While many Solidoodlers will likely use their 3D printers to output Yodas, gearsets or bunnies, one New Zealander decided to take 3D modeling to the next level. With the average price of an Aston Martin DB4 running in the hundreds of thousands of dollars, Ivan Sentch decided to go one better by printing a full-scale Aston Martin DB4 replica.

Prior to Aston Martin’s ejection-seat enabled DB5 in James Bond’s Goldfinger and Thunderball, there was the DB4. Not nearly as famous as its iconic successor, the DB4 was the first to incorporate the new Italian designed body and upgraded drivetrain. But with prices running between US$330,000 and $1.7 million for a restored DB4, the opportunity for the average person to own one remains highly elusive, which is exactly the dilemma faced by New Zealander Ivan Sentch.

A relative noob to 3D modeling, Sentch has only been working with the Solidoodle printer since January of this year. When asked why of all the cars he chose to recreate a DB4, he says it not only has the styling but 4 seats, which will come in handy when transporting his kids.

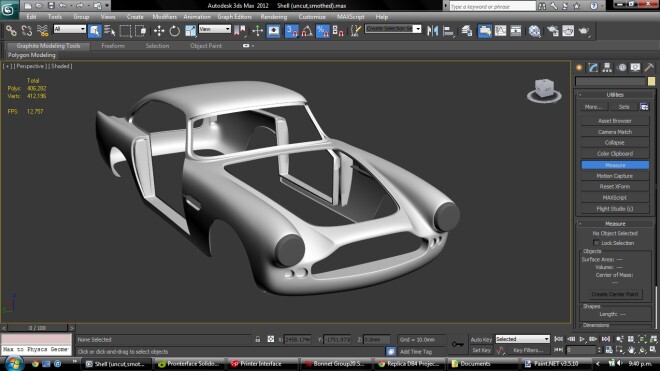

The design for the DB4 came from a 3D drawing from TurboSquid.com. The detailed rendering was then torn down to its base design so he could modify it to better suit his vision.

To design the cross sections, Sentch used Autodesk’s 3DS Max modeling software and then sent it to the Solidoodle printer for rendering. Since the printer can’t output full scale fenders or doors, he had to compile these sections by outputting hundreds of smaller, bite-sized forms. These forms, averaging around 105 x 105 mm (4 x 4 in), are then mounted on the section’s framework and glued into place.

In a Q&A with Solidoodle, Sentch points out that although he only has 28 percent of the car’s body left to print, plus the dash, he still has an awful lot to do before the car is finished. Once the printing is complete he then needs to take a mold of the DB4 by applying autobody filler, then sanding, then repeating until the body has a glassy finish. Once it reaches this stage then a mold prep compound can be applied, followed by more sanding and painting.

For the DB4’s drivetrain and engine, Sentch plans on harvesting bits and pieces from a 1993 Nissan Skyline GTS, as parts are relatively cheap and readily available in his native New Zealand. He's also considered making the faux DB4 electric (much to the horror of the purists), but he says the thought of messing around with batteries and accompanying logistical issues will probably make the electric option unlikely.

Sentch will continue to Solidoodle his way about the printed DB4, but expects the project will take another 4 or 5 years to complete.

Source: Replica DB4