Engineers from Ohio State University have developed what they say is the world's first microscope lens capable of obtaining three-dimensional images. While 3D microscopy has already been achieved, it has previously required the use of multiple lenses, or of a single camera that moves around the object being imaged. The new device, however, is just a single lens that sits in place on an existing microscope.

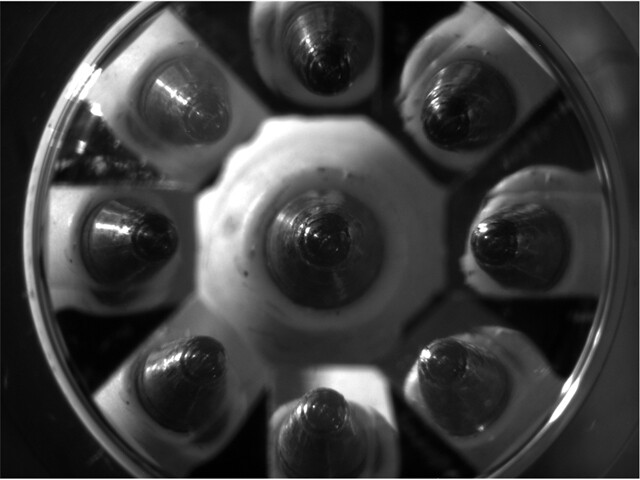

The prototype lens was cut from a transparent piece of polymethyl methacrylate thermoplastic, also known as acrylic glass, using a commercially available milling tool outfitted with a diamond blade. The finished product, which is about the size of a fingernail, looks not unlike a gemstone. One side has a central facet circled by eight other facets, while the other side is flat. Unlike a gemstone, however, the facets are not intended to be identical – each one differs very slightly from the others in size and angle, which is an example of what is known as "freeform optics."

The lens was attached to a camera-equipped microscope, which looked down through the faceted side, to objects placed underneath. The nine facets each captured their own images of the objects, from slightly different angles. Those nine images were then fed to a computer, which combined them into one three-dimensional image. Objects that were observed included the tip of a ballpoint pen, with a diameter of about 1 millimeter, and a micro drill bit, with a diameter of just 0.2 mm.

It is hoped that once commercialized, the lens could be used in the manufacturing of microelectronics and medical devices, for medical testing, and to replace more complex machine vision systems. Although the prototype was machine milled, the engineers state that subsequent lenses could be less expensively produced via traditional molding techniques.

Allen Yi, associate professor of integrated systems engineering at Ohio State, and postdoctoral researcher Lei Li led the research. Their findings were recently published in the Journal of the Optical Society of America A.